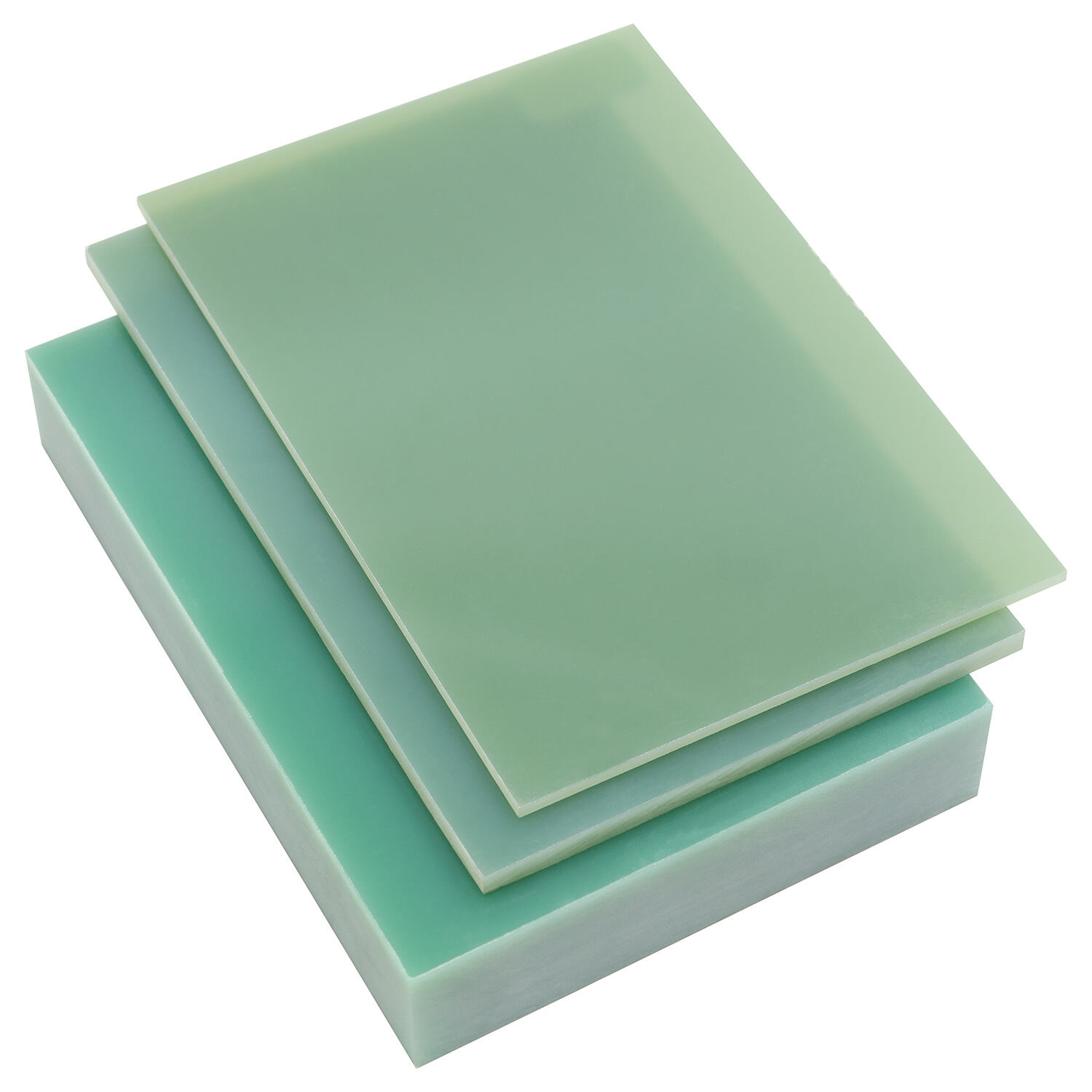

One such type of material that is used in making these handles is 1.5 mm G10 Sheet. It might sound complicated but it is a handy concept when dealing with real world engineering and design. In this article, you will find out why 1.5 mm G10 sheet a good option for some of the projects that you may be working on.

First of all, 1.5mm G10 sheet is extremely tough and wear resistant. It features layers of tightly compressed fiberglass and resin. It is a hard impact, water and heat resistant combination only. Its powerful, it can withstand many obstacles and go great distances without breaking. In addition to this, it is also light in weight that can be too handy when you have to hold or lift it for different purposes.

1.5 mm G10 sheet is widely used in many applications due to that influence across various industries. It commonly used for parts of airplanes and spacecraft, because it should be strong material but at the same time light weight as well. Over the years, it has also become common in manufacturing circuit boards for use with a wide variety of electronic devices. This is because the de-icer presents high insulation properties, which means it does not easily allow electricity pass through. In addition to this, it is a strong polymer and therefore can be use for knife handles etc as they are able tolerate high temperatures and numerous chemicals with no breakage.

The main benefit of using 1.5 mm G10 sheet is that it allows for easy customization. You can shape it into any form or size, and you can create a mold that suits your requirements. Because it is so versatile, this means you can use the style for testing some new ideas or prototypes before settling on a final piece. Even better, it is surprisingly simple to handle and work with making drilling holes or sanding the edges of this material (in a very traditional sort-of-aluminum-siding kind) even more effortless if you're short on time.

A popular construction and design material for many industries, the G10 sheet offers a unique range of properties for fine work. It is widely used for manufacturing parts of machines and equipment. This material is chosen as it provides the best of both worlds, strong yet lightweight which people prefer over heavier options. This makes it more manageable for handling and fitting. It is also widely employed in construction. For example, you can be able to produce parts of the building which needs tensile or apply in different weather conditions and so on.

The marine industry Another valuable function for 1.5 mmG10 sheet involves theboat communities. Same as plywood it is best used on boat parts that require waterproofing and come in contact with salt water. It can be formed into hatches, doors and decks for boats. It is also commonly used in surfboard fins, as it offers a lightweight and durable alternative to ensure the best possible performance on water.

This is a G10 sheet 1.5 mm, which means it can be used pretty versatile for various purposes. As a result, it is also possible for the surface to be painted differently in color and as decorative purposes. This allows you the flexibility to design some interesting designs yet still gain from its resistant optimal strength. At the same time, it is simple to clean and should be used in these contexts with a strong eye towards hygiene so they are adaptable for kitchen or medical environments.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.