-

Functions and Materials of Motor Slot Wedges

2026/01/22The motor slot wedge is an important part in the manufacture of motor, it plays a vital role in the normal operation and performance of the motor. Motor slot wedges are typically installed in the stator slots to secure the stator coils. As one of the...

Read More -

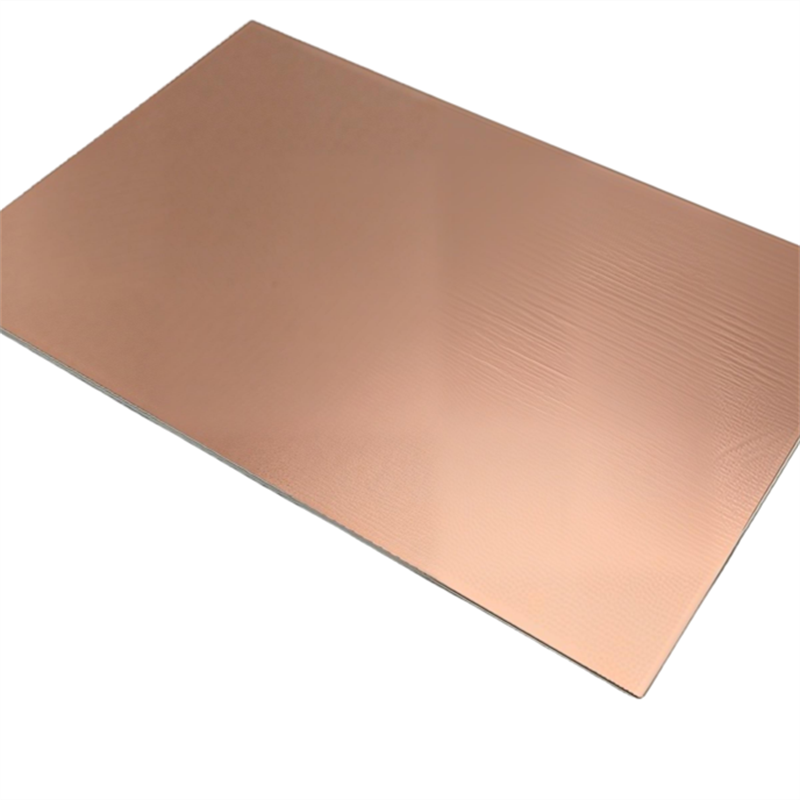

What are the common material used for printed circuit board (PCB)?

2026/01/15One of the common materials in printed circuit board (PCB) manufacturing is Copper-clad laminates (CCLs) which are manufactured by impregnating resin with reinforcing materials like wood pulp paper or fiberglass cloth, then laminating copper foil on ...

Read More -

Why is Durostone the Ideal Material for Wave Solder Pallet?

2025/12/19Durostone is is a high-performance fiber-reinforced composite material developed by Germany's Röchling Group, which is composed of thermosetting resin (such as epoxy or polyester resin) and glass fiber mat reinforcement, and processed through hi...

Read More -

Is G10 Material Safe for the Human Body?

2025/12/06G10 material is basically harmless to human body under normal use conditions, but it may release tiny substances when processed or treated at high temperature. It is a kind of composite material synthesized from glass fiber and epoxy resin, which has...

Read More -

G10-CR Epoxy material: Tailored for Ultra-low Temperature Industrial Equipment & Components

2025/12/02G10-CR Epoxy material: Tailored for Ultra-low Temperature Industrial Equipment & Components G10-CR epoxy glass fiber laminate is a specialized variant of standard G10, engineered for extreme low-temperature applications. Specifically designed f...

Read More -

High-end Material: Polyimide Glass Cloth Laminate

2025/11/22High-end Material: Polyimide Glass Cloth Laminate Polyimide glass cloth laminate, also known as bismaleimide insulation board, is a rigid polyimide resin laminate formed by hot pressing alkali-free glass cloth impregnated with polyimide resin as the ...

Read More -

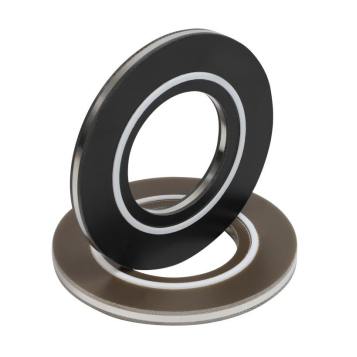

High-performance Flange and Gasket Kit for electrical and industrial equipment

2025/11/15There is special type of composite flange and gasket featuring high-strength epoxy resin insulating sheets (G10/G11) bonded to both sides of stainless steel plates. This design maintains the steel's structural integrity while providing exceptional in...

Read More -

GPO3 Halogen-free Flame Retardant Technology and Its Applications

2025/11/03GPO3 Halogen-Free Flame Retardant Technology is an optimized solution for enhancing flame retardancy in GPO3 (Glass Fiber Reinforced Unsaturated Polyester Resin Insulating Sheets). The core innovation involves using halogen-free flame retardants (exc...

Read More -

Comparisons of G10, G11, FR4, and FR5 Epoxy Fiberglass Materials

2025/10/23G10, G11, FR4, and FR5 are all epoxy glass cloth laminates. Their key differences lie in temperature resistance, flame retardancy, and material composition, while sharing identical substrate structures and core functionalities. Common characteristic...

Read More -

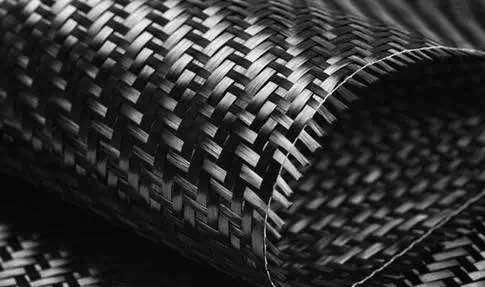

21st Century’s Top Advanced Material: Carbon Fiber

2025/10/19Carbon fiber, a high-performance material with over 90% carbon content, is produced through the decomposition of organic fibers into a carbon backbone structure under high temperatures.It possesses the inherent characteristics of carbon materials whi...

Read More -

Is the phenolic cotton fabric tube a flame-retardant product?

2025/09/23The flame retardancy of phenolic cotton fabric tubes depends on their material properties and the specific application scenarios. 1. Inherent Flame Retardancy Phenolic resin, which serves as the primary adhesive in phenolic cotton fabric tubes, is na...

Read More -

Mechanical processing——the cornerstone of manufacturing

2025/09/19Mechanical processing, formally known as machining, is a manufacturing process that modifies the shape, dimensions, surface quality, or properties of raw materials like metal, plastic, and wood using specialized equipment such as lathes, milling mach...

Read More

EN

EN