GRP bolts are a key part of construction. These are special bolts that are both substantially more durable and have a longer lifespan than a traditional bolt. In this text, we will learn about GRP bolts: what they are, why they are so important in construction, the benefits of using them, how they are made, where they are used, and tips for how to put them in and take care of them.

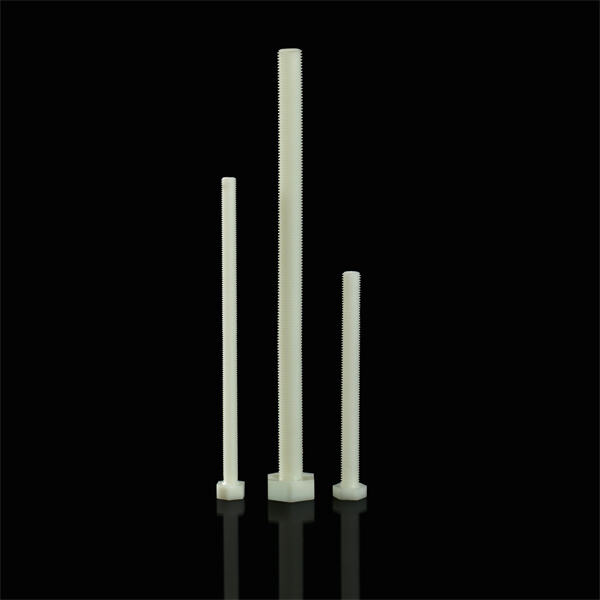

There GRP is an acronym for Glass Reinforced Plastic. GRP consists of plastic combined with glass fibers. The combination of these two materials delivers something powerful, lightweight, and durable. This strong material is used to create GRP bolts, which are popular in the construction industry because they offer advantages compared to standard metal bolts. For instance, they ensure safe and secure buildings and other structures.

Reasons to Use GRP over Metal Bolts GRP bolts are lighter than metal bolts to begin with. That makes them easier to get about and handle, especially as workers are placing them. 2nd: GRP bolts are a lot stronger than metal bolts. That means that they can be used in difficult situations or parts where metal bolts would break or fail. Third, GRP bolts, unlike steel or other metal bolts, do not rust, thus making GRP bolts far superior in withstanding water/air damage over time period.

Another major advantage is that GRP bolts are more eco-friendly than metal bolts. But they contribute to reducing waste, since they are made of recyclable-resources. Also, they are devoid of harmful chemicals so they are safer for the environment. This makes GRP bolts a more sustainable option not only for construction, but our home as well.

Now, let's explain the manufacturing process of GRP bolts. It begins with glass fibers mixed with a type of plastic. The mixture is then injected into a metal mold, which shapes the bolt and forms the threads that hold it in securely. After the mixture hardens and turns solid, you take out bolt from the mold. Then it is cleaned up to smooth out the edges and remove excess material to ensure it is prepped and ready for use.

In buildings, GRP bolts are crucial for keeping different parts of the building connected, including the walls and the roof. They hold everything in place and can even help buildings survive bad weather. GRP bolts are also used to connect various parts of wind turbine blades, facilitating their efficiency in energy generation from wind.

Second, don’t over-torque the bolt. If you pull the GRP material too tight, it will crack, and the effectiveness of the bolt will decrease. Third, GRP bolts should be inspected regularly for signs of wear or damage; this is generally best practice. This includes checking for cracks in the material, signs of rust, or other issues. If you do encounter any issues, you should replace the bolt immediately for safety.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.