BMC moulding – have you heard about it before? So, let’s see what it is about! BMC — Bulk Moulding Compound It is a specific combination that is made from various substances that can be molded into durable and solid things. BMC moulding is the process in which this mixture is placed into a mould, which is like a special container that forms the material. Then, the mould is compressed and heated to harden it into a solid shape. Due to this process, BMC moulding is an excellent method in making robust and durable products. Factories and places with mass production often apply this method to produce different types of products.

When it is time to create products, there are a lot of great justifications for deciding on BMC moulding. And one prominent one: It can save you money. It is a fast and smooth process. That means it takes less work and fewer workers than other methods of producing things. So, you are in touch with your nearby supplier which reduced the expense of production. Graduating from an amateur to an established manufacturer helps you fetch better pricing for your goods and land more deals.

Another advantage of choosing BMC moulding is that it can be formulated to replicate almost any shape and design accurately. BMC moulding material can readily take on a range of different shapes. Here the versatility this adds to designing your products. Moreover, products created in this manner are highly durable as well. There is a high chance that they will last longer than those which are made using other manufacturing methods, really counts for the customers looking for reliable products.

Standards: It is a must to have a company that works and adheres to the standards of BMC moulding. Professional manufacturers know how to deal with any possible issues that arise in the production process. That experience can help make sure all goes smoothly.

Technology: Another good thing to look for is a use of latest technology in BMC moulding, so look for such a company. State of the art technology can streamline the manufacturing process and create the best quality products. Including high-end approaches and equipment allows the business to suit your unique needs and demands perfectly.

Speedier Production: BMC moulding is considered a speedier production technique. What this means is you can get more things done in less amount of time! If you want to meet customer demand and bring products to market faster, then shorter production times help.

BMC moulding is ideal for complex shapes and advanced products. The material is easily manipulated into dozens of different shapes, so you can know you are getting the exact shapes and features that you need. This technique is also applicable to create specialty items such as electrical devices, automotive parts, and medical apparatuses. BMC moulding is used to prepare final products that are strong and great reliable to be used in various important applications.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

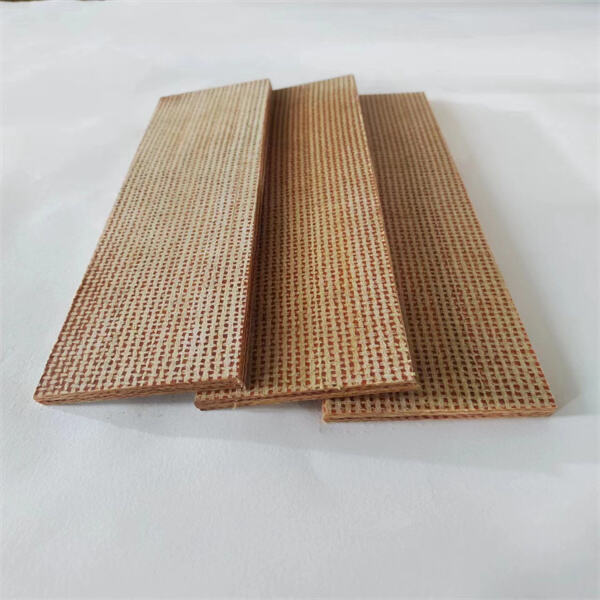

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.