Carbon fiber is an amazing material, very strong and oh-so light. The product's durability and long-lasting features make it a perfect option for the things that need to go on flawlessly. The RDS carbon fiber sheets with other materials can also produce stronger and high-quality products. This unique quality of the material contributes to making it applicable in multiple areas such as sports, engineering and much more.

Carbon fiber is perfect to make strong products with a low weight. The RDS carbon fiber tubing has been implemented over many years for aircrafts and space shuttles that are not only under pressure, but need to help whist and all the stress of taking off into the air. Sports gear for example, car parts and some medical tools have carbon fiber in them too. These might benefit from it more, thanks to carbon fiber's strength and lightness which helps athletes perform better.

One of the main advantages carbon fibers has going for it is how incredibly light weight. The RDS carbon fiber material makes them easy to pack and use — unlike stuff from, say… carbon fiber. Think about a heavy backpack — if it was made out of carbon fiber, carrying one would be so easy. Carbon fiber is also very strong, this means that it can support a large weight before collapsing or getting destroyed. This makes it a perfect selection for things like construction material and sports equipment which require strength not to get damaged easily.

The simple answer is its special structure. It is made up of small pieces of carbon that stick together. Those small carbon pieces ensure that the material is both hard and can bend. The other materials that can mix with carbon fibers make what is commonly known as a composite. The composite is both light and hard, making it a good material. Finally, the two characteristics make the carbon fiber unique, hard and can take any form. That means it can take almost any shape; thus, it can be used to make an airplane’s wing and a bicycle frame, among other items.

The first classification of the uses of carbon fiber is that users involve advanced engineering. Advanced engineering occupations are concerned with products that are light and hard. The carbon fiber molding is a good match because it can mix the two makes easily.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

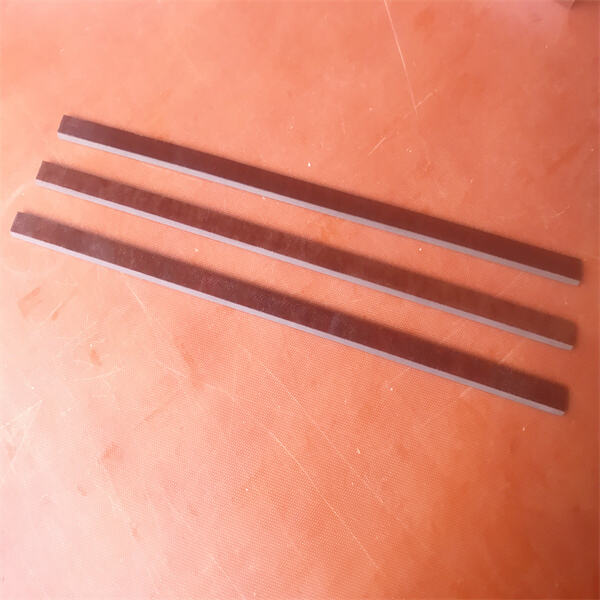

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.