Have you ever heard of sheet which is fiber reinforced plastic? It is a unique type of material that is being used more and more in various industries, for good reasons! This article tells us everything we need to know about the benefits of fiber reinforced plastic sheet and discusses what it is comprised of, how they are contributing their share in changing industries around us. We will also examine some real-life use cases and take a look at examples.

However the most excellent properties of fibre reinforced plastic sheet are that it is so incredibly strong for its weight. This makes a lightweight material that is much easier to carry and work with than other materials as strong. This is why it can be utilized for various applications such as being a construction material to build houses, used in automotive industry to make cars and even the aerospace industry so that airplanes will have strength without weighing much of course.

Fiber reinforced plastic sheet is great since it does not rust or decompose easily. This allows it to be kept safe and in-tact longer while being used around harsh chemicals, or saltwater just like a deckhand trying not have their clothes damaged. This makes it a perfect option for environments where rust and corrosion are the main problems such as in coastal areas or industries sites.

Fiber reinforced plastic sheet is into a new era, it has been more commonly used in various types of industries while people recognize its only features. For instance, in construction industry its being used to substitute the conventional heavy materials like steel and concrete. Because it is far lighter than these substances, so not only can you move and transport the resulting structures with more ease – they are also extremely strong and robust.

With so many application possibilites and industries, fiber reinforced plastic sheet can be the perfect solution. For construction, it can be turned into lightweight but strong beams or panels to support large buildings and reduce costs in building those projects. With vehicles, it could produce lower-weighted part for cars-trucks-trains which would boost fuel efficiency and reduce emission.

If you would like to see fiber reinforced plastic sheet in practice, there are many products available on the market that use it. One example is modern automobiles, that now to a significant degree use fiber reinforced plastic sheet for body panels and other components. This helps in losing weight of the cars, thereby making them fuel efficient. Well, if you do this can be a positive change in the environment and it will save drivers some gas money!

While an even more dramatic example would be the Boeing 787 Dreamliner airplane. This incredible plane utilizes over 50% combed fiber reinforced plastic sheet for its build before you jump out of your seat, here is the full scoop. This makes it fourfold lighter than planes of same size. It also saved fuel by being lighter, and is an environmentally greener airplane than many others.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

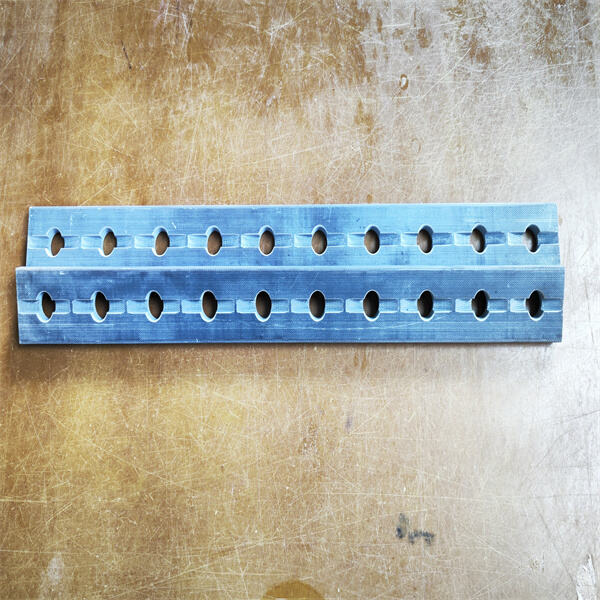

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.