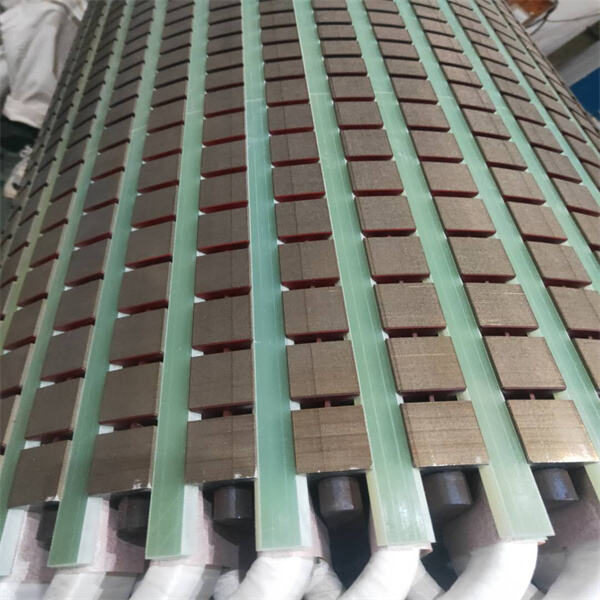

You know the FR4? It is a gummy glass fabric with comparable weight and physical area as textile that you utilized in house hold work smudged by glue: fiber-glass remove along with an adhesive called epoxy resin. This specific composition is what gives FR4 it own unique properties. Many use it in electronics, since it can be used to create things like printed circuit boards — or PCBs. These PCBs are vital for a number of electronic instruments In this article we will take a closer look at the 5 top benefits of using FR4 material on your next project.

Strength: FR4 material is one of the strongest components out there, period. It can resist the high temperature and heavy pressure without any break or damage. It is therefore suitable for use in tough environments such as electrical appliances. For instance, FR4 frequently applies for equipments in aerospace industry which are under heavy crashes or automotive applications where electronic components must be durable and solid.

Durability: As a result of its terrific security features, FR4 product never ever influences or bends its shapes like various other dielectric material. This is important for PCBs because they need not only size, but shape to be steady in order to work properly. If the PCB is bent or warped, then there may be issues connecting at the circuits, which can cause a computer not to work all. Therefore, a very robust material like FR4 helps to make any electronic device long lasting and hassle free.

If high-frequency is required, FR4 can be the first choice -- it has excellent electrical properties. Also, this is a good insulator that is not easily conductive (that means electricity won't run through it). Very crucial in maintaining the separation of different circuits on.printed circuit boards else they cause short-circuits FR4 also has a low dielectric constant so it does not store electrical energy, allowing signals to move fast and freely across the board.

Finally, you have the FR4 material which is by far one of the most common available all over planet earth. This makes it easy for companies and individuals to locate this service online, buy access to implement the same in their projects. For manufacturers, having a material on hand when they need it is crucial to keeping their production lines flowing. When you are creating electronic items for various purposes, the critical thing is to create reliable products and this consistency of quality can only be maintained if your manufacturer uses FR4 material.

Boosted Performance: Then, FR4 material adds value to the overall performance of electronic devices. Due to its exceptional electrical features our engineers can create faster and more energy-efficient circuits. This is essential for things like computer and all this high technology gadgets which that communicate with the outside worldManufacturers have been squeezing ever more circuitry into silicon, a process called scaling, but it's something of an extreme sport.

Another material benefit of FR4 is that it significantly reduce the problems with respect to reliability which make electronic device last longer. Since the substance is so hard and durable, this composition can help make more reliable electronic devices. This is very important in the application where reliability is an essentia l thing like medical devices and safety systems.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

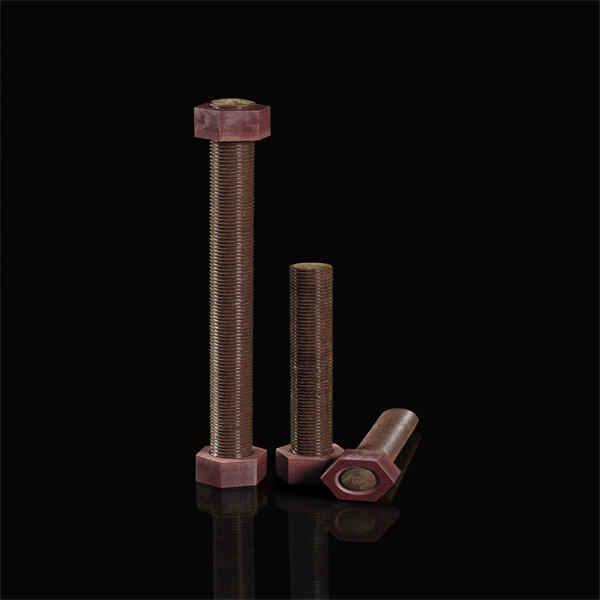

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.