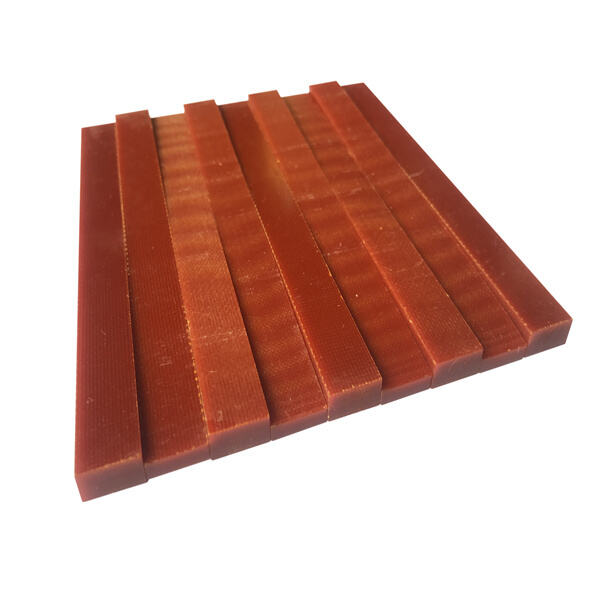

This G 10 epoxy fiberglass sheet is a unique item manufactured using microscopic glass fibers and a specific resin which becomes solid when exposed to heat, known as epoxy. Think of a bunch of very thin glass threads woven together, and tied together with a very strong super glue. And that is how this incredible material is made!

This material is extremely strong and durable. Therefore, it can undergo excessive labor without smashes and needs. If something is built from G 10 epoxy fiberglass sheet, it can have a long life. Imagine it like a superhero material that does not easily become tired or weaker.

One of the great things about this material is that it loves water! It will not be damaged if it gets wet. Even ocean salt water doesn’t damage it. This means this special material can be your boats, your water toys and other things you may have that go in water. This material is very popular for sailors and people working in a marine environment.

Its G 10 epoxy fiberglass sheet manufacturing is like putting a tough quilt together. First, workers take very fine glass fibers — much thinner than a hair. They carefully intertwine these fibers with each other. Finally, they pour in a resin called epoxy that bonds all of the fibers together before it sets. This makes the material reinforcing vertically, from top to bottom.

This material appeals to makers because it can do so many jobs. It’s lighter than metals like steel, so it won’t weigh things down. It also doesn't rust, which is a huge plus as well. It can be molded into just about anything — parts for machines, tools or specialized equipment.

The G 10 epoxy fiberglass sheet also reaches the top when it comes to applications where resistance and strength are vital. lots of airplanes use it to make parts that need to be lightweight but incredibly durable. Boats use it to create components that can deal with rough water. Some factories use it in machines because it can work hard without falling apart.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.