This is very high strength plastic, G10 FR4 material. It combines different substances through methods ensuring that it can be made to have properties unlike any other compound. That is the topic of this article: how G10 FR4 material will stay as strong as it can be and getting used in various applications.

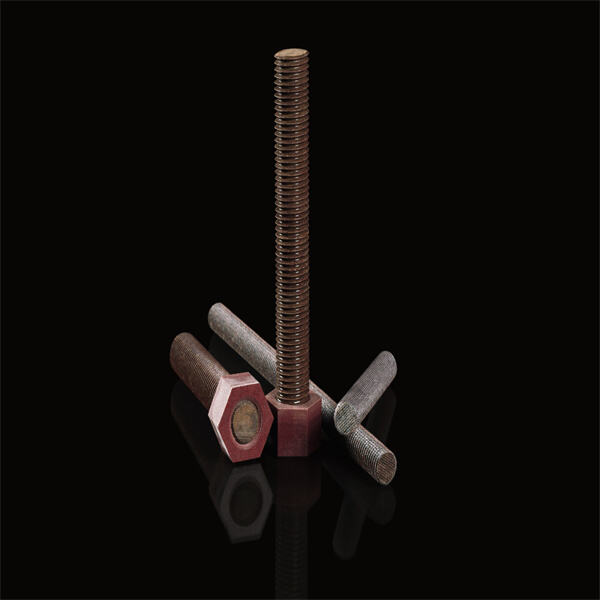

The material of G10 FR4 is tough and durable. It's very strong, so it can be used to manufacture things like parts for airplanes and automobiles — even military equipment. G10 FR4 material is well-known for its strength and this comes from the way that it is made, using layers of fiberglass bonded with resin. These fibers add strength and resistance to the material while resin encapsulates them which will protect it from damage or wear.

Benefits of G10 FR4 Material for Manufacturing and Creating Products Due to this, there are no chances of breaking it and can be used over a long period as well. It is also highly heat, flame and moisture resistant. This makes it ideal for use in extremely demanding applications where other materials would be inappropriate or malleable enough to malfunction. G10 FR4 material is widely used in creating a wide range of goods whether that may be airplane parts, parts for electronic appliances or something as simple as our kitchen cookware but without G10 being the suitable solution to produce this.

There are a few special attributes of G10 FR4 material that make it an optimal choice for fabrication. For instance, it is highly resistant to various chemicals -a property that can be used in areas where other materials would rapidly degrade and become unsafe. Further, it functions as a great insulator. It is capable of shield electronics from the electrical and/or thermal load or other hazardous conditions.

G10 FR4 provies protection to the electrical parts and components. These parts are to be protected from external damage and insulating properties helps it tremendously which is very important for the safety & reliability of electrical devices. Where other materials would wear down, the sturdiness of G10 FR4 means that it should last longer. So you can see why G10 FR4 is popular within many electrical applications such as circuit boards and transformers, … etc

Can stand great toughnessHeavy weightWith a G10 FR4 material you can suffer very hard conditions. Highly resistant to heat, flames and moisture, during tough jobs in a rough environment. This material furthermore is able to handle high pressure that can be very helpful in any system working with liquids, for example hydraulic systems. It has even been used in the aerospace industry: combined with copper, G10 FR4 material is implemented as parts for rockets and satellites that must withstand severe conditions.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.