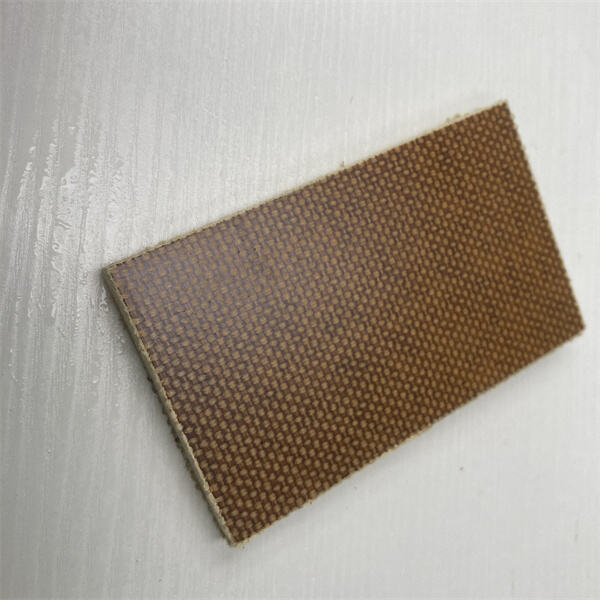

Its very helpful in many kinds of projects so we are going to talk about it. Well, this something special is actually known as glass epoxy sheet. It is type of material that makes many goods and projects better. RDS is a brand for High-Quality Glass Epoxy Sheets that may come in handy if you do a type of work where achieving a perfect surface and/or a perfect cleavage plane is of utmost importance. Now, lets have a closer look and discover more about this incredible material.

The strength of glass epoxy sheet is incredible. That means it can support a great deal of weight without snapping or bending. This characteristic is crucial since several projects need materials that can hold heavy things without falling apart. Another important advantage is that it has the ability to withstand a variety of chemicals, making it useful in environments with a wide range of substances. So if you're using liquids or other raw materials that needs a safe surface to work on, glass epoxy sheet wont get ruined. This material is also resistant to both fire and water, so it is an ideal material for many applications from kitchens to factories where there is a potential for heat.

Glass epoxy sheet is an excellent material for consideration if you are working on a project requiring a strong and durable material. That material can be used in a wide range of applications, including electrical components, automotive components and components for airplanes. If you use the right type of fr4 glass epoxy sheet, you can definitely significantly improve the strength of your project and ensure a longer life. Having a good foundation is crucial if you want your project to remain in a good state over an extended period. So, if you make a toy or a tool, it will resist damage and it will last long with a sheet of glass epoxy.

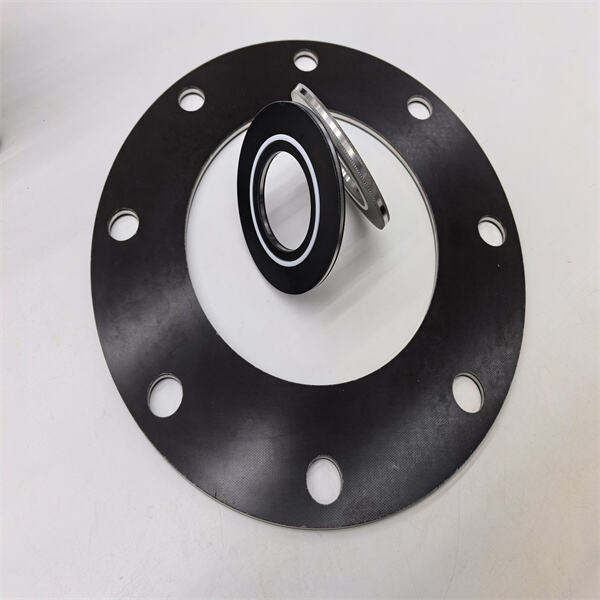

The versatility of RDS glass epoxy sheet is evident in its ability to be used in a variety of applications. There are several applications for metal cladding, for example, it is commonly applied in the production of electrical components such as circuit boards required for electronics functionality. In addition, it is used in the automotive industry to manufacture critical components like brake pads, gears, and bearings, which aid in the smooth running of vehicles. In the aerospace industry, fiber glass epoxy sheet is employed to manufacture components that withstand extreme heat and pressure, important for aircraft flying at high elevations. Additionally, it is utilized in the construction sector for building materials such as floors and roofs that must be strong and long-lasting. As glass epoxy sheet has various use in different industries, it has become a material that is relied upon in many situations.

Next, let’s discuss what glass epoxy sheet consists of. Note: The material consists of glass fibers and epoxy resin. Its strength and rigidity are contributed by glass fibers, while epoxy resin serves a binding function that tightly holds the glass fibers together. When combined, these elements form a strong, lightweight material that is extremely valuable in a wide variety of applications. Glass epoxy sheet is known for its high tensile strength, ensuring that it will not break even when pulled or stretched, as well as its good electrical insulation properties, preventing any electrical leakage, along with a high degree of chemical and heat resistance. Its these qualities that make it so easy to work with as it can be cut and molded into numerous different sizes and shapes to serve all sorts of purposes.

When it comes to manufacturing processes, RDS glass epoxy sheet is truly true game-changer. This can facilitate a far higher quality of products being manufactured, fewer mistakes and a more enhanced level of customer satisfaction. This indicates that customers are generally satisfied with the products they purchase and fiber glass epoxy sheets. Moreover, glass epoxy sheet can lower production costs thanks to its resistance to various substances. That means factories have to use fewer resources or materials to make their products. It can also help speed up the production; it comes in various shapes and sizes so it can be molded quickly improving the efficiency of work.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.