As one of the important tools for making electronic devices, solder pallet material is often used by many factories. Their function is crucial as they keep different parts in position and these packages are joined with a material called solder. A key to success is in choosing the correct solder pallet material, and this may present some challenges as there are various types of materials containing a unique set of benefits for you production process that we will come across.

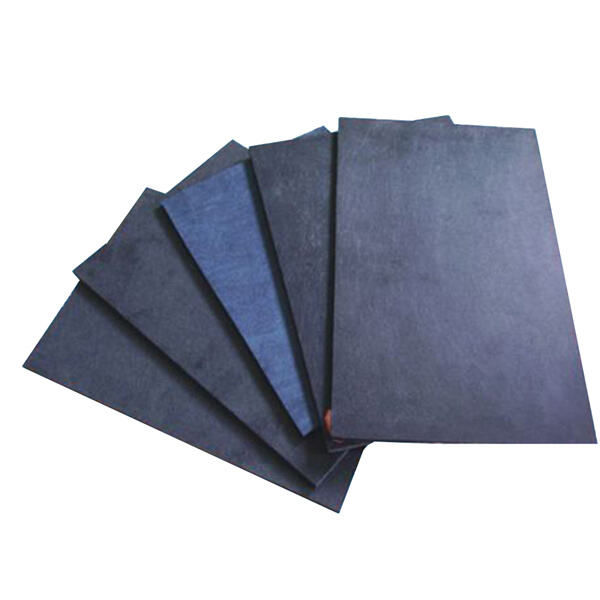

Fiberglass: This is another material that solder pallets are constructed from. Fiberglass is highly durable and guarantees long years of usage. Because of this, it can hold much weight and pressure that is why for jobs like mounting the electronic parts to an object; steel brackets are perfect. All this strength is important to deliver good performance in the face of a high level of duty from its normal use, bringing more peace at all stages until assembly.

Strong and durable but expensive pallet materials are easy to maintain, have superior heat resistance and chemical resistant capabilities compared with their inexpensive counterparts. This is important because that way, it protects the fragile little electronic components during assembly of those parts. If these parts are not subject to damage, they will last longer and operate more efficiently. This can result in less of a final design hassle, and that is something every business are after.

Selecting the right solder pallet material will help increase your productivity and overall product quality. One example is choosing a relatively cooler material so that the electronic components are not spoilt during assembly. As such, there is less chance of damaging these components that are often extremely expensive to replace. By minimizing the risk of damage, a lower quality final product is higher in reliability for consumers.

There are many several types of solder pallet materials but choosing the right one requires contemplation on vital considerations. Some of the important points to look at is what kind of electronic parts you use. A variety of materials, each corresponding to the different components and functionalities may be desired for safety and effectiveness. You are using a kind of material and the best choice for your material will also depends from where you are working. Some materials are not going to withstand the humidity or others will melt in really hot conditions.

Remember to choose the material that is just right for your use, also consider its price point and life span as well as strength and bolt capability if it can survive under heat or high / low PH. All of these factors come into the play, to make sure you choose the material that fits your business needs like a glove. Choosing the material of your right solder pallet, is not easy at all and you should make a trendy research before investing.

One of the most than essential business for electronic parts businessmen Investing in good solder pallet materials due to this causing poor production can occur. If you opt for budget materials, your products can easily end up being low in quality. This can result in increased downtime due to repairs or replacements and limited lifespan of the electronic components you are assembling. This can damage your business slowly over time.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.