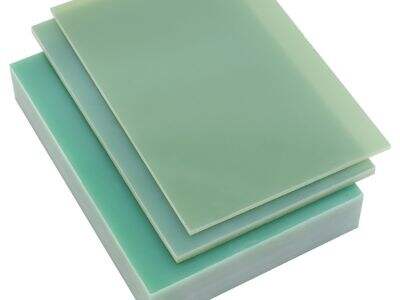

Epoxy fiberglass laminates are manufactured by bonding together strong glass fibers and epoxy, which is a sticky resin. This product combination makes for a hardy sheet that can withstand plenty of pressure and bending before it cracks. These laminates are used in many factories because they are light and very strong. So, when something is pushing or pulling on them, they do not crack or become distorted very easily. This another reason why these parts are a favorite choice for applications that see hard working days. We offer these laminates at RDS in a meticulous manner to ensure they are durable and work austere enough for rough environments. The glass fibers and the epoxy working together is like being on a team where everyone takes part in carrying the load so nobody gets hurt

The Way Epoxy Fiberglass Laminates Tolerate High Mechanical Stress in Industry

When devices remain in movement, their components have to endure a good deal of stress as well as bending and trembling. Epoxy fiberglass laminates can get this type of misuse because of the method they are actually built. The glass fibers within function as little bit of ropes that maintain the lot coming from breaking down. Those fibers birth the bulk of the tons as well as tension, along with the epoxy simply keeping all of them in position as well as safeguarding all of them coming from damages. Photo a connect, however rather than steel cable televisions within the seal, certainly there certainly were actually solid plastic strands; that's one thing such as exactly just what these laminates are actually performing. At RDS, our team guarantee our laminates include the appropriate equilibrium of fibres as well as epoxy towards get hefty manufacturing facility tons. For instance, in conveyor belts or even device protectors, these laminates will not wear quickly. They endure fractures that generally happen because of repeated bending or even striking. Sometimes machines vibrate such as insane as well as it triggers things towards breather down truly rapidly. However these laminates are actually good at saturating up the resonances to begin with, which spreads out the power throughout the fibers therefore nobody place kinks. As well as the epoxy material avoids sprinkle as well as chemicals coming from damaging down the fibers, to ensure that also in difficult atmospheres such as chemical vegetations or even steel stores, the laminates final. The laminate our team are actually understood for is actually the factor our clients, when they inform our team over and over again that machines operate much a lot longer without needing components to become altered out due to our laminates. Our team also misuse all of them, through flexing as well as pushing hard multiple opportunities towards view if they preserve their framework. This extensive screening enables our team towards deal products that never ever stop working, also under one of the absolute most severe technical tension

Why Wholesale Mechanical Component Suppliers Design Epoxy Fiberglass Laminates

Wholesale suppliers require materials that are not just strong, but also workable and dependable. Epoxy fiberglass laminates are ideal for this. They come in big sheets that can be cut or formed into various components easily. At RDS we have developed these laminates with consistent quality and the suppliers know exactly what they get every time. The laminates don’t allow much warping or shrinking when cut, a feature that saves manufacturers time and money. Meanwhile, their lack of bulk keeps shipping costs down, something wholesale providers who send out lots of orders are bound to appreciate. Another good aspect about these laminates is that they provide decent resistance against heat and electricity. That makes them great for parts in motors, switches and other mechanical things that become hot or carry current. Suppliers know the laminates won’t fall apart if a user needs to drill, sand or glue them. This flexibility allows parts to be made faster and with fewer errors. At RDS, we also ensure our laminates adhere well to paint or coatings, allowing suppliers to provide good-looking finished parts with longevity. From what I have learned working in the industry, suppliers won’t use laminates that produce waste when breakage is a problem during processing. Not only does this save you money, it is more environmentally friendly. Indispensable for wholesale suppliersTo find the right balance is a common problem that every wholesale supplier who must rely on materials must solve – how can you strike an affordable price and also provide quality work? For those looking to add some variety with their options, epoxy fiberglass laminates from RDS are the best bet when it comes to keeping everyone happy

Selecting Epoxy Fiberglass Laminates for Products That Last and Are Stress Resistant

When you are deciding on the materials to create durable and long-lasting products, then epoxy fiberglass laminate is your best bet. These laminates are produced by stacking and bonding layers of fiberglass cloth with epoxy resin. It results in a substance that is strong but lightweight, allowing it to withstand a lot of pressure and stress without breaking. "We specialize in manufacturing premium Epoxy Fiberglass Laminates that assist you in building products that last

In order to find the right epoxy fiberglass laminate, you should consider how the product will be utilized. For instance, if the product is going to endure heavy weight or bending, then you will need laminates with more fiberglass layers. More plies, stronger and more bend-resistant. Also of importance is the epoxy resin used. Some the best-suited epoxies for fiberglass adhere well and remain strong, even when applied in wet or changing-temperature conditions. - RDS Technologies uses proprietary epoxy formulas which bond the laminate to your specification under high pressure and heat; this technically advanced process ensures durability

The thickness of the laminate is also something to take into account. Thicker laminates can withstand greater mechanical stress, but are also heavier. Solid RDS comes in a variety of thicknesses, giving you the optimal strength-to-weight ratio for you. It also matters how you stack the layers. If the layers are in good alignment, then the laminate will be stronger in the direction that typically experiences stress

When deciding on a final product, it’s wise to consider the environment in which this product will be deployed. RDS epoxy fiberglass laminates work well in many applications, including outdoor installations, where they resist moisture and chemicals. Basically, your product won’t get damaged quickly due to water, sun or harsh chemicals

To summarize, if you want high quality long-lasting and stress-resistant products, consider carefully your choice of epoxy fiberglass laminates. Consider the layer count, epoxy type and thickness; their configuration. When you work with RDS, you receive a laminate that can take a beating an remains durable for the long-term

How Mechanical Stress Tests Compare Other Materials to Epoxy Fiberglass Laminates

When we want to know how strong materials are, we typically stress them mechanically. These tests reveal the way materials respond to forces like bending, stretching and twisting. Epoxy fiberglass laminates from RDS perform exceptionally well in these tests, relative to a wide variety of other materials

For instance, when you compare epoxy fiberglass laminates to metals such as aluminum or steel, the former is significantly lighter while being equally strong. That means products built with RDS laminates can be easier to transport or pack out while maintaining strength. Metals can easily bend or get dented, but epoxy fiberglass laminates tend to snap back to their original form following bending. This is because the fiber glass fibers inside make it possible for the laminate to resist damage

Epoxy fiberglass laminates have far greater tensile strength than plastics. A lot of plastics tend to break or shatter when overly stressed, whereas RDS laminates are better at resisting bending and impact. They are not easily worn out and can maintain their shape and firmness over time. This is ideal for anything that requires something sturdy and durable

A particular advantage of the epoxy glass laminates is that they are resistant to fatigue. Fatigue occurs when a material is repeatedly stressed, in the same way as bending a paperclip back and forth until it fails. RDS laminates have better tolerance to such damage than many other materials. This makes them best suited on parts that move or experience repetitive forces every day

Another plus: In tests that check how materials fare under heat, epoxy fiberglass laminates perform admirably. Some plastics and metals weaken when heated, but RDS’s epoxy laminates remain tough even at elevated temperatures. This makes them great for products that need to function in warm or fluctuating climate conditions

In summary, when you compare some epoxy fiberglass laminates from RDS to metals and plastics; it becomes clear that they are light-weight, robust and thrive on repeated stress or heat. These attributes contribute to product safety and longevity

Where Epoxy Fiberglass Laminates Are Preferred in Mechanical and Structural Uses

RDS epoxy fiberglass laminates are found wherever high strength, electrical or thermal insulation is required. By virtue of their strength, lightness, and durability, these laminates are useful in mechanical and structural applications

One of the popular uses is for building boats and ships. Boats require materials that can withstand water, sun and strong waves. RDS epoxy fiberglass laminates wont swell or soften in contact with water. This is how boats are able to last and remain safe on the water

Another promising territory is in manufacturing parts for vehicles, including cars, trucks and airplanes. These parts need to be strong enough to protect passengers and keep operating even if they are jostled or crashing. RDS composites provide strength while keeping vehicles from becoming too heavy, a savings in fuel as well as enhanced performance

In sports gear, one of the best known uses is to construct tough and flexible gear from epoxy fiberglass laminate. For example, surfboards and bicycle frames must be light, but also capable of withstanding pressure and blows. The RDS laminates are the ideal blend of strength and lightness

Epoxy fiberglass laminates are used in buildings and bridges to add strength to concrete and steel structures. They reinforce parts that bear heavy loads and resist damage from weather and chemicals. That makes structures potentially safer and longer-lasting

Finally, epoxy fiberglass laminates are useful for machinery and equipment. If parts move or carry heavy loads, they require materials that don’t wear out fast. RDS laminates also hold up better over time, saving machines for long, hard-working lives

In general, RDS epoxy fibreglass laminates are effective in applications where strong light materials are required. Whether in boats, cars and sports equipment or buildings and machines, these laminates help to produce strong products that withstand mechanical strain and have a long service life

Table of Contents

- The Way Epoxy Fiberglass Laminates Tolerate High Mechanical Stress in Industry

- Why Wholesale Mechanical Component Suppliers Design Epoxy Fiberglass Laminates

- Selecting Epoxy Fiberglass Laminates for Products That Last and Are Stress Resistant

- How Mechanical Stress Tests Compare Other Materials to Epoxy Fiberglass Laminates

- Where Epoxy Fiberglass Laminates Are Preferred in Mechanical and Structural Uses

EN

EN