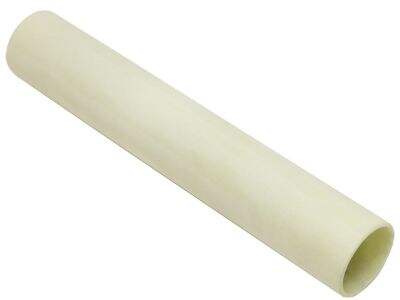

The first one is the epoxy glass tube precision machining. This process involves cutting and shaping the tubes carefully so they are the right size and form. We at RDS understand how essential precision machining is for high-quality epoxy glass tube manufacturing. In this tutorial, we will cover the importance of accuracy and provide you with a step-by-step guide for making perfectly machined tubes. We will also discuss working quickly and with precision, tools for cutting, and quality checks.

Knowing the reason behind why the precision is necessary

Allows us to create tubes that can withstand high quality control standards. Precision machining makes sure that the tubes are the correct size and shape, with no errors and with smooth surfaces. Even small mistakes can cause the tubes not to fit together correctly. Through using the right tools and paying careful attention to details, we can produce epoxy glass tubes exactly based on what is your clients' needs.

Now lets get into how we begin the process of making our perfectly machined epoxy glass tubes.

Starting off we will need to measure and mark the tubes correctly so they are cut to the correct length. Then, we firmly secure the tubes using a vice or other tool to prevent movement in our assembly process. The cutting tool is then used to naturally cut the tube. We plan what we had and after each cut we check the Epoxy Fiberglass Tube to make it is what we want. We can create epoxy glasses tubes that are ready to use by following these steps.

The right tools are key to working as efficiently and accurately as possible with epoxy glass tubes.

We use precision made quality cutting tools that are specifically manufactured for cutting glass and various other hard materials at RDS. These are sharp and sturdy tools that allow us to make clean cuts across these tubes. We employ advanced techniques such as CNC (computer numerical control) machining to ensure that every cut is the right one. This allows the creation of quality Epoxy glass tubes with precision and accuracy as we work with the help of right tools and techniques.

Understanding the tools and techniques of precision machining is one of the most important things to achieve great results.

This means the cutting tools need to be sharp and precise so the tubes can be cut cleanly, without damaging them. Depending on what we want to do, we can use different tools, like drills, saws, milling cutters, etc. We also sometimes grind, polish, and laser cut the fiberglass tube. If the right tools and techniques are used, we can always ensure that the epoxy glass tubes have been prepared under high-quality standards.

All you have to do is keep checking for quality control so you can guarantee the perfection of the epoxy glass tubes.

Every stage of the machining process is inspected at RDS with stringent quality control measures. Before starting, our team inspects the tubes for any issues that could impair the end result. When machining, our operators monitor the tools and processes to confirm proper functionality. We source gas hollow fiberglass tube in bulk and perform a secondary check post machining for size and quality. These quality control steps guarantee that each epoxy glass tube we produce will be flawless and ready for use.

Table of Contents

- Knowing the reason behind why the precision is necessary

- Now lets get into how we begin the process of making our perfectly machined epoxy glass tubes.

- The right tools are key to working as efficiently and accurately as possible with epoxy glass tubes.

- Understanding the tools and techniques of precision machining is one of the most important things to achieve great results.

- All you have to do is keep checking for quality control so you can guarantee the perfection of the epoxy glass tubes.

EN

EN