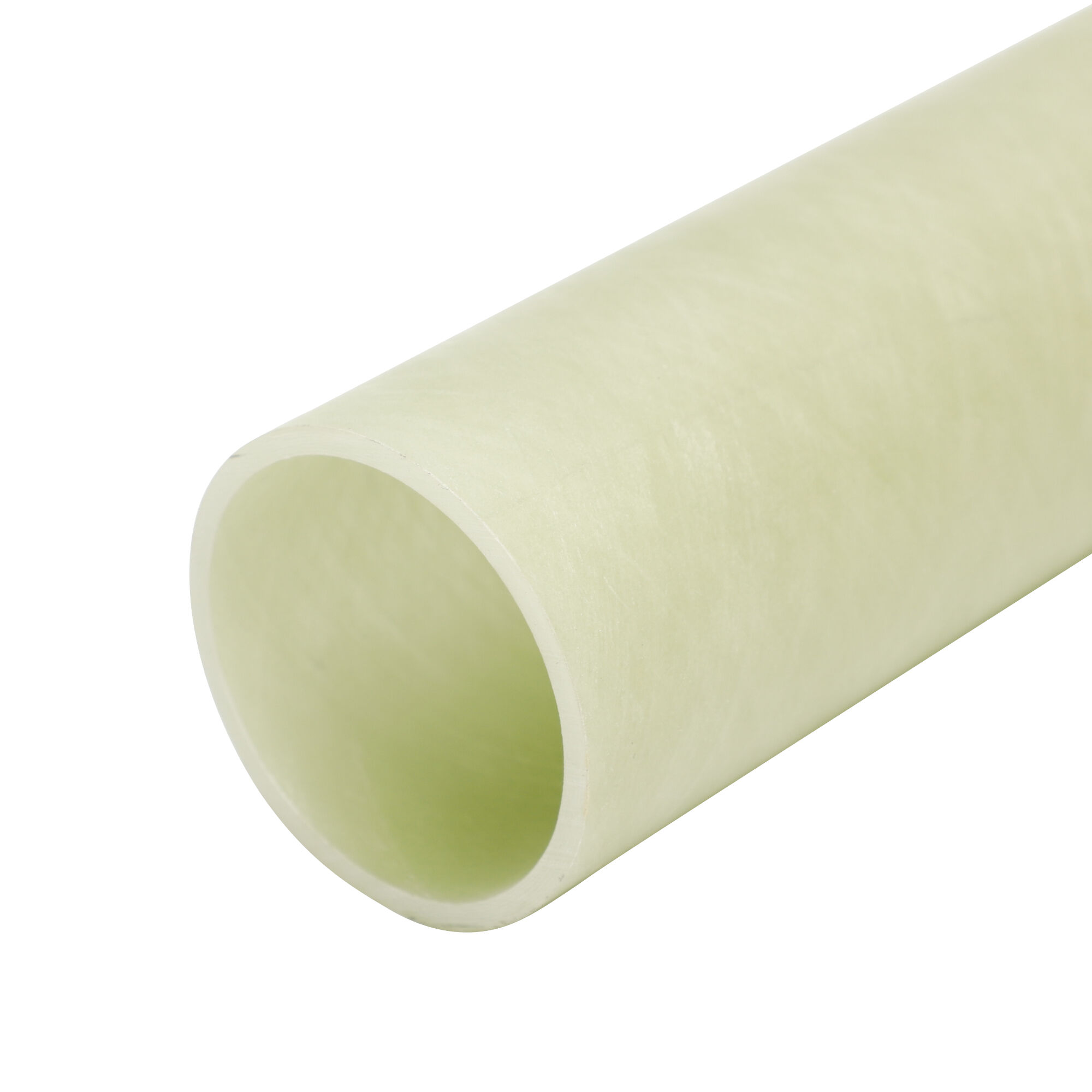

In the aerospace industry, for example, the goal is to make things stronger and last longer. RDS Epoxy Fiberglass Laminate support this by being strong and able to endure extreme heat as well as chemicals.

In the aircraft business, pieces are often ruined during flights. These sensitive components are encased in epoxy glass tubes. They are lightweight but strong, which is useful in situations where weight is a consideration. This is like experiencing more reliable and efficient devices if we tend to put these RDS epoxy glass tubes in aerospace companies.

In industries such as electronics, these tubes also sit guard over sensitive components from electrical issues and external conditions. The RDS epoxy glass tubes offer strong insulation, ensuring vital components are functioning well.

Moisture, dust and other things that can harm electronics are kept out by epoxy glass tubes. By keeping their products safe, this enhances electronics manufacturers and even helps them improve their quality.

Increasing the dependability of engine components is critical in cars and power stations. Engine parts that come between the glass tubes filled with epoxy, causing the epoxy to harden. This process protects engine components from heat, vibrations, and rust, making them more durable and efficient. RDS Epoxy Fiberglass Tube are capable of withstanding high temperatures and harsh environments, contributing to better engine performance.

In vehicles, these tubes shield sensors, wires and other vital components from heat and vibrations. This automatically leads to better performance and longer-lasting vehicles for automotive companies that use the RDS epoxy glass tubes and this, in turn, keeps the customers happy.

Answer: They are trained to keep medical equipment safe and clean, which is very important for the safety of patients and doctors from germs. The types of glass tubes are widely used in medical tools like catheters and surgical instruments; epoxy for glass tubes. They create a protective barrier between the device and the patient. RDS epoxy glass tubes are produced under strict medical standards to ensure medical devices are safe.

These tubes also are resistant to chemicals, which is beneficial for cleaning operations. By using RDS epoxy glass tubes, medical device companies can ensure their continued safety, effectiveness, and regulatory compliance.

Thus, the oil and gas sector requires high-performance solutions. Many applications of epoxy glass tubes are in drilling, pipelines, and refineries. Due to their ability to withstand high pressure, temperature, and aggressive chemicals, RDS epoxy glass tubes are ideal for the polymer processing industry.

In drilling, these tubes shield sensors and other critical components from the harsh conditions of underground. Oil and gas production companies that use RDS epoxy glass tubes can make drilling easier and more reliable and make production more profitable.

To sum up, RDS Epoxy Fiberglass Rod are a valuable solution for industries such as aerospace, electronics, automotive, medical devices, and oil and gas. They also assist in insulation and protection, reinforcement for adsorbents, improving durability, promoting efficiency and reliability, and safety and sterility for separation and high-performance applications. RDS epoxy glass tubes are ideal for making upgrades to mission-critical systems and components for company operations, providing exceptional quality and reliability.

EN

EN