Large number electrical equipment is used today in our life. It makes possible our lights, phones, computers and many other devices we rely on every day. With out this gear the world would be a real challenge to do something as simple as switch on some lights or use all our favorite technology. As is the case with anything else we use, electrical devices might break or stop functioning as time goes by. This is where the RDS epoxy glass tube comes into play! Because of this, many different applications find it very beneficial as these special tubes help function electrical equipment as it should for a long period of time.

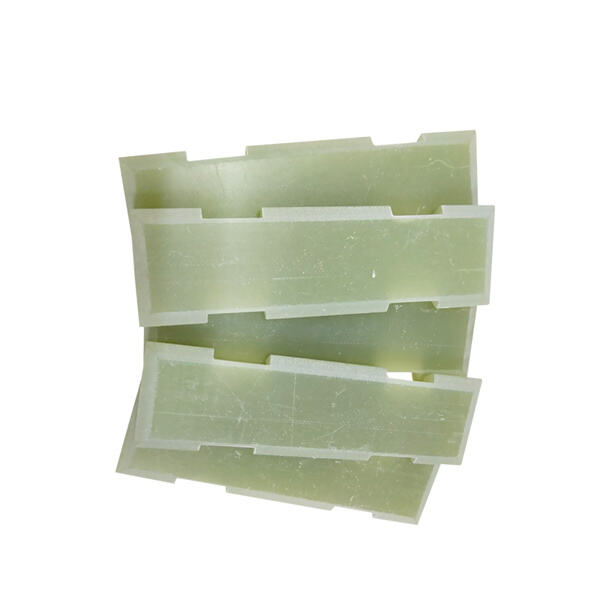

Epoxy glass tubes consist of a combination of sticky epoxy resin and woven glass fibers. This makes for a really strong, light weight, and work-able medium. This is where the epoxy resin comes in and is key as it serves as an insulator for the wires that are used inside the tube. This insulation protects the wires, preventing them from the risk of wear or contact with other parts of the electrical device that could lead to malfunction. The rolled glass fibers add additional layer of protection making the tube stronger. Doing this allows the tube to prevent it from cracking or breaking, even if under a large amount of pressure.

Epoxy glass tubes are useful even for daily home electronic equipment. RDS epoxy tube is also quite useful in large industries which need durable materials. They have very high strength, making them suitable for high performance applications. In the aerospace industry, for instance, these tubes are frequently used to protect and insulate wiring in airplanes and spacecraft. The wiring has to be safe and reliable in such difficult environments, so this is very important. InsulatorsThey are mainly used in substations and transmission lines to keep wires up and prevent them from getting direct contact with people but they are also being used in the telecommunications industry where cell phone towers and other important communication equipment, wiring, etc are protected and insulated with the help of insulators. That means they have a central role in maintaining global connectivity.

The strength of glass combined with the resiliency of epoxy is what offers rds epoxy glass tubes unparalleled strength that can withstand a multitude of trials. RDS glass epoxy tubes are heat-resistant, so can operate effectively in hot weather. They are also resistant to chemicals, which helps in areas where strong substances are used. And they are resistant to moisture, which means they won’t degrade when exposed to water or humidity. As a result, they are extremely reliable in difficult environments that other materials may falter. These tubes also possess a high dielectric strength that isolates them from high-voltage electricity. This is immensely significant because it prevents any escape of electrical flows that could disrupt the devices.

In sectors such as aerospace and telecommunications, the materials utilized by manufacturers must meet exceptional standards. So, they need materials that are robust, safe, and long-lasting. Epoxy glass tubes such as RDS fulfill these requirements plus more. The addict help to resist the shot would be providing you with phenomenal strength, terrific durability and highest insulation for electrical gear. It also prides itself on its commitment to quality and ensures that its customers are happy with its products. This indicates that RDS goes out of its way to keep its products reliable, consistent, and easy to work with, a critical element for manufacturers.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

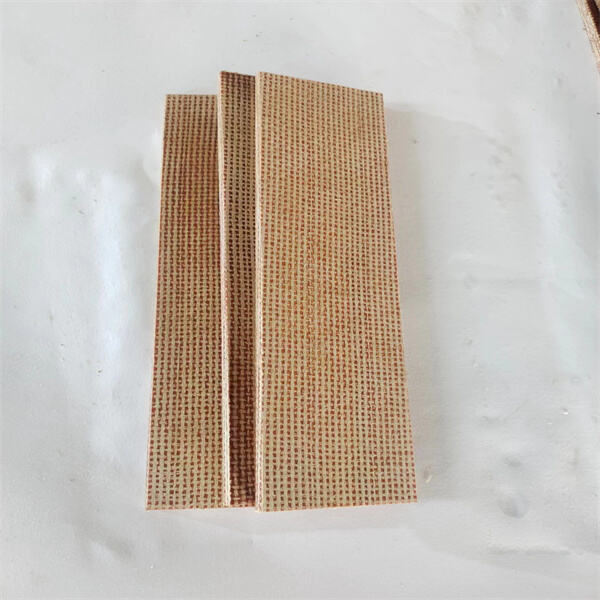

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.