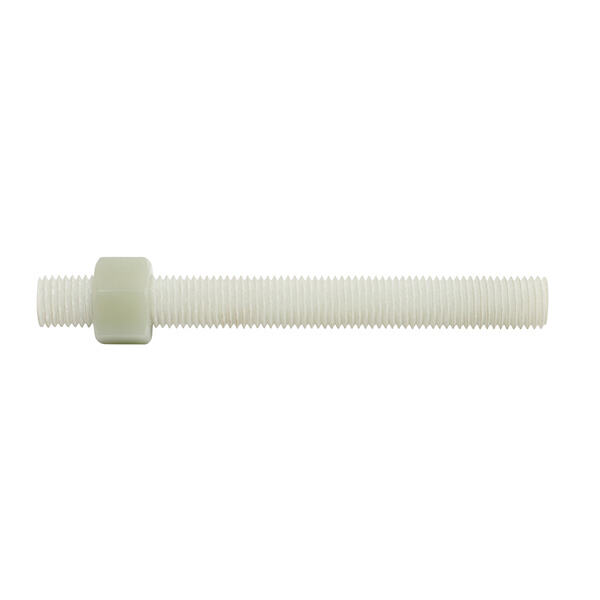

I am sure you have heard of what they call fiberglass bolt. While that may sound a bit weird, it is indeed an actual object used in a lot of important ways! Fiberglass bolt: A fastener has been a term that is used to describe the material which holds together things like screws and nails as known. The bolts are also special and made of a light material called fiberglass, said to be as strong as steel. Fiberglass is a plastic that's combined with millions of tiny glass fibers to become composite. The weave of these fibers gives the material great tensile strength, which allows it to be used as Bolts.

Though in contrary, the fiberglass bolts have an upper hand on these steel tubes; even if they are as robust and tense as a steel bolt (typically used to do work under heavy-duty category), but yet so light for weight. This weight difference is actually quite significant as it allows you to use them in spots where you might need a slew of bolts but do not want everything getting too heavy. For example, fiberglass bolts can be found in aeroplanes. Airplanes need thousands of bolts in order to keep the parts together and make sure people do not tumble right out of write armed planes. But if the bolts are too heavy, they can add weight to a plane and cause it not perform as well. The fiberglass bolts make the total weight lighter, hence making the plane easier to fly and less of a fuel guzzler too.

A further excellent quality of fiberglass bolts is that they are strong and most determine not to have any elements in the end. And the reason behind it is that fiberglass, as a material, can last much longer than some other materials out there. Fiberglass barn bolts will not let you down when it comes to longevity.

Fiberglass bolts also are corrosion resistant. Corrosion is a damaged state of metals (mostly to steel) due long exposure in water or chemicals process. This causes the metal to rust and for it makes it weaker or less supportive. But, this does not rust like that of metal. That means fiberglass bolts are a good option where there is high humidity or chemical activity, like outdoor projects or in proximity to water.

Fiberglass bolts are also easy to make, which helps keep their costs down. They are created by interweaving glass fibers that have been reinforced with a composite polymer resin to create the mesh. This was a much simpler process than the processes used to forge steel bolts, which must be heated in a furnace and shaped into their final form. This less complicated manufacture means that fiberglass bolts can be turned out fast.

Anyone who has spent time on a boat understands that marine equipment and environment do not coexist easily. Keep in mind that due to the saltwater and air, metal parts can rust easily. This is why fiberglass fasteners also known as bolts are called the perfect solution to be used for marine applications.

Fiberglass screws should not rust, and are impervious to salt air or other environmental damage. They are also lighter than steel bolts would be, and that can translate to overall better performance of the vessel. What is more, it can not conduct electricity as some bolt made of the metal. This becomes very critical on a boat as electrical systems are usually in close proximity to water lines. The use of non-conductive bolts can also avoid electrical issues which is why Fiberglass Bolts are an excellent choice for boat builders and repairers.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.