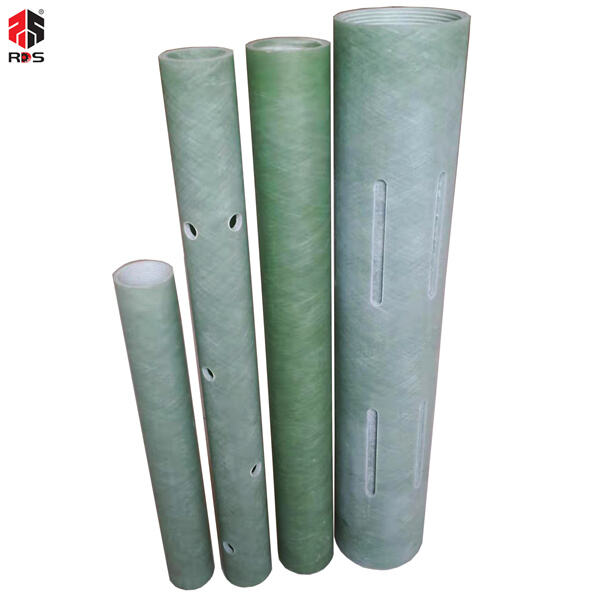

Constructed from a very durable and pliable material known as Fiberglass tubing, this has applications to numerous industries. It is built by melting small fibres of glass together to essentially create a type of plastic. These substances make fiberglass tubing unique and help in a wide range of purposes.

There are a number of great qualities that make fiberglass tubing so popular. In the first place, It is too much tough that it can not break even under pressure or weight rathe quickly. The second is lightweight so we can handle and transport easily. Third, flexibility, it can be flexed without breaking. And because it is so stable in all temperatures, fiberglass tubing can be utilized anywhere other types of materials may not hold up as well. These characteristics of fiberglass tubing is what makes it a viable solution for high -load scenarios.

Fiberglass tubing is mainly used as electrical conduits. An electrical conduit is a tube that transports the electric wires safely from one place to another. Fiberglass tubing is perfect because it also non-conductive. As you can see from the above highlighted feature of PVC which is that it does not conduct electric current this makes actually least suitable for using in electrical carrier systems. The materials in the fiberglass tubing provide a high degree of protection and can guard against potential electrical hazards.

Fiberglass tubing is used in many different lines of work. It is used in the construction industry as a material for building. Builders like its durable and light-weight out, which benefits utilizing it in different tasks. Fiberglass tubing is a common part in the automotive industry these days, with it even commonly used for parts such as exhaust systems. Fiberglass tubing is used for converting exhaust gas from a liquid to gaseous state effectively. Additionally, it is highly utilized in the marine industry to fabricate boat parts such as hulls and decks. Its resistance to water and corrosion mean its the perfect candidate for offshore boats that see constant mingling between saltwater.

Structural — Making things like bridges, buildings etc.Fiberglass tubing is of perfect use when it comes to structural applications. This is a go-to for these projects as it packs the right strength to weight ratio that makes shaping simple yet provides all necessary sturdiness. Moreover, fiberglass tubing does not corrode so that it will be ideal for outdoor items as well. Therefore it is long-lasting and can last years without the need for repairs or a change, which saves money in the long run.

A lot of fiberglass tube is also easy to work with. It can be tailored to particular requirements of the project. It can be colored to suit a design, shaped into various forms and molded to fit individual requirements for instance. This flexibility makes fiberglass tubing an ideal solution for a wide range of design challenges and project sizes.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.