Fiberglass sheets are one of the most important material that finds application in several areas such as, construction, transportation and other industries. One of the reasons to know just how much they cost is that it will help you decide on your next fiberglass sheets so please read carefully.. By knowing the pricing, you can decide what options are best suited for your needs and pocket.

The cost of fiberglass sheets are generally based on two major things: how much the world desire them and then; How many sheets that they have for sale. It is called supply and demand. If a lot of people are interested in purchasing fiberglass sheetsthen prices can go up. Conversely, if not that very much individuals are buying fiberglass sheets for sale then the selling price will certainly go decrease as a result of excessive amount connected with sheets above potential buyers. But the prices can also be impacted by the costs of sourcing raw materials, paying workers and shipping its products to customers. But should any of those costs increase, sheet prices may as well.

Fiberglass sheets could cost more in an area where workers are well-compensated for their labor, if the company manufacturing them is located there. That has a cost to it, though — the maker needs to make sure their employees earn living wages. Likewise, if the fiberglass sheet is made from expensive raw materials, then you may end up paying a higher price for that part. All of these factors combine to determine the cost fiberglass sheets will set you back.

For a number of reasons, buying fiberglass sheets can be a wise decision. Fiberglass is a strong and lightweight material that does not readily rust. They are versatile and can be used in a variety of ways because of this. In the case of a fiberglass sheet, you can make things such as boats, cars and yes — even buildings. Its range of uses has proved it to be valuable material across industries.

If you are considering purchasing fiberglass sheets, then one must consider the long-run benefits on which they can rely. Fiberglass sheets may have a higher upfront cost than some other materials, but their resilience and life-span can pay off in your favor down the road. So you will spend a little more upfront, but save yourself from replacing them as often which is financially wise.

If so, then you might want to consider places that offer the best discounted rates for fiberglass sheets. The simplest (and possibly best way), of course, is to get various price quotes from many manufacturers. This gives you some idea of a competitive price. You should also consider that what the status and quality of manufacturer is in mind while you are buying it. Check the reputation of manufacturer — well a reputed one will provide with some good quality sheets which is add-on point!

There are many variables to take into account both on the manufacturing side of making fiberglass sheets and in determining pricing. Prohibitive cost — In order for fiberglass sheets to be of good quality, it is necessary that the manufacturer spend money on raw materials, labor and purchase expensive equipment. All these costs increase and that kind of affects the sheets's end price.

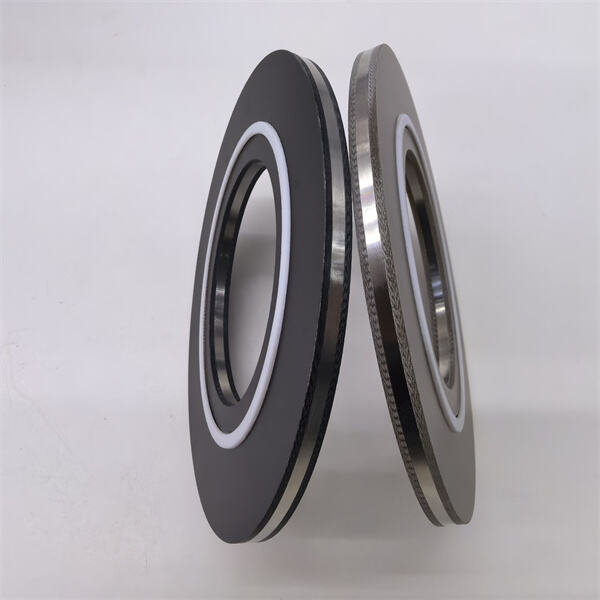

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.