So, when we think about strong materials what do we have in our mind? Hard and strong, like metal or concreteSuggestions: Have you heard of fibreglass board sheets? These sheets are made of a unique blend of materials and increasingly trendy for many purposes. Here, we will also discuss the numerous advantages of fibreglass board sheets including how they are created and where in different industries it can be used.

Fiberglass board sheets are a lot stronger than building paper Fibreglass is a mixture of plastic and tiny glass fibres. This amazing combination gives fibreglass a strength that plastic or standard glass does not come close to having. Its robust nature allows fibreglass board sheets to withstand harsh weather patterns, such as wind and rain elements which makes it suitable for outdoor projects and uses.

Yet another good thing about fibreglass board sheets is they provide you with level of resistance next to water and chemicals. Fibreglass for instance, can soak up water and get damaged but the material you choose here does not absorb any water. That makes it will not. It is therefore interesting for example within swimming pools, water tanks and wherever chemicals are handled. This means that fibreglass board sheets are durable but will also work in many different surroundings.

Their versatility means they are excellent boardsheets, one that can be used for many different applications. They can become panels on building walls, cover buildings from the elements including roofing material or even insulation to keep a building warm and cool. Apart from this, they are widely used in the transport industry to make boats, campers and trucks use as it is light weight but incredibly strong. The light, tough design makes this combination very helpful to ensure that whatever vehicle Roewe has in mind can withstand the rigors of high-speed duty.

They are used for a variety of purposes in farming, including fibreglass board sheets. They can serve as panels for greenhouses, which are beneficial in growing plants strong and healthful — safe inside from predators. And, they can serve as shelter for farm equipment to protect it from the elements. Besides, the boards are used to print board for animals that benefit from shelters such as sheds of livestock. Fiberglass is often a good choice in these applications because it does not stain and cleans easily. Because fibreglass won't hold germs like some other materials, it is safe for use around pets.

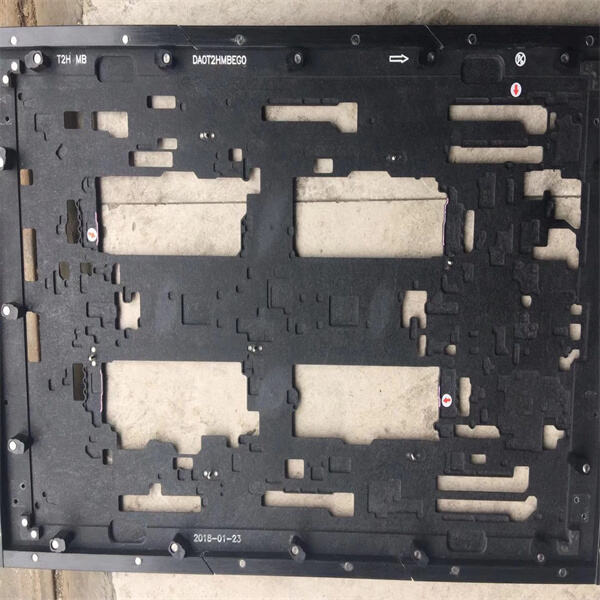

How fibreglass board sheets are made is an interesting & pertinent thing to know about. Manufacturing consists of layering and compressing together fibreglass with a sticky stuff referred to as resin or polymer. When combined, the two create a sturdy sheet that is able to be cut into many forms and sizes dependent on what it will be used for. The fibreglass is woven strands of glass coated in resin. Between these layers and sheets the individual components are stacked, then hot-pressed to create a solid sheet or laminate of thickness 0.5–8 mm.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.