One of the greatest qualities pultruded FRP has going for it is its extreme durability. For that reason, it becomes an ideal material for constructing structures such as beams and other essentials of buildings. Pultruded FRP does not corrode or damage as readily as other materials, making it much longer lasting and lower maintenance. The durability is important on building projects where quality and safety need to be assured over many years.

Moreover, Lightweight is also a fairly great feature of pultruded FRP. Consequently, it can be moved and installed effortlessly, saving you a lot of time during construction. Workers can transport it without having to use heavy equipment because it is not too heavy. Furthermore, pultruded FRP is commonly employed to construct bridges and make components of automobiles. Its flexibility has actually made it among the most prominent options for builders and suppliers.

Pultruded FRPs are used by many companies because they offer very good strength-to-weight ratior to weight ratio, which makes the more enticing option. That is to say, the use of pultruded FRP can save both material and manpower costs. It is also easier to handle, thus more companies can bring faster results from it. While it may not seem very productive at first, this efficiency is crucial for the completion of large projects on time and within budget.

Besides economic, pultruded FRP is also environmentally friendly. It is a material that can be recycled again, so they do not accumulate much waste in the landfills. It is a recycling process that will not harm the planet and promotes cleaner environments for businesses. Manufacturers can demonstrate a commitment to the environment and responsible material sourcing by selecting pultruded FRP.

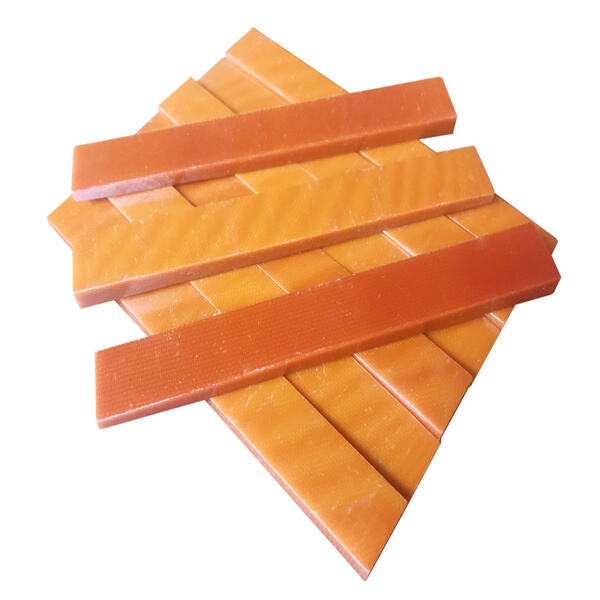

Pultruded FRP is well known for its high strength and wear resistance. It is applied in a variety of sectors, from building and construction to marine craft products like boats. Pultruded FRP is also weathered and fire resistant as well chemically in a harsh environment with the need for lasting 20 Years. This makes pultruded FRP resistant to harsh conditions that can destroy structures over time.

Compared to traditional materials such as steel, wood and concrete, pultruded FRP is a truly green choice. It is manufactured from reused materials, this implies that fewer new assets are required to be produced. Add to that the fact pultruded FRP can, at life end, be in turn recycled and it offers a natural asset for environmental-conscious builders or manufacturers.

In addition to being sustainable from an environmental perspective, pultruded FRP is also very energy efficient. It also requires significantly less energy to manufacture than most other materials, resulting in a reduced carbon footprint. That energy efficiency can be a boon to manufacturers hoping not only to save some money on production costs, but wanting also to stay green priced about utilities.

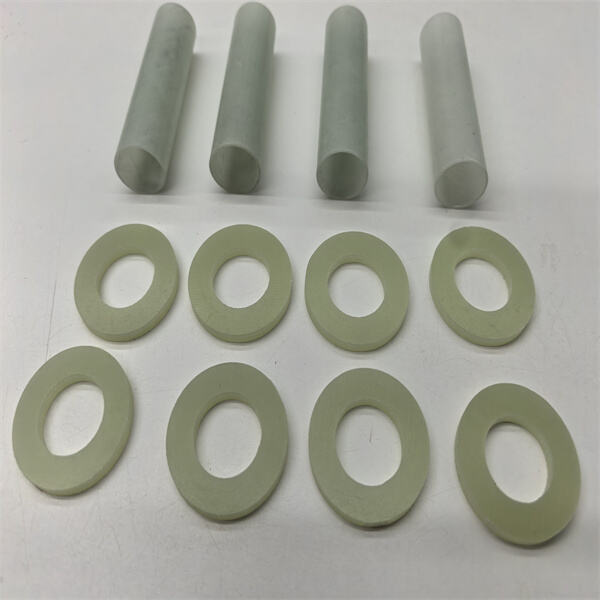

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.