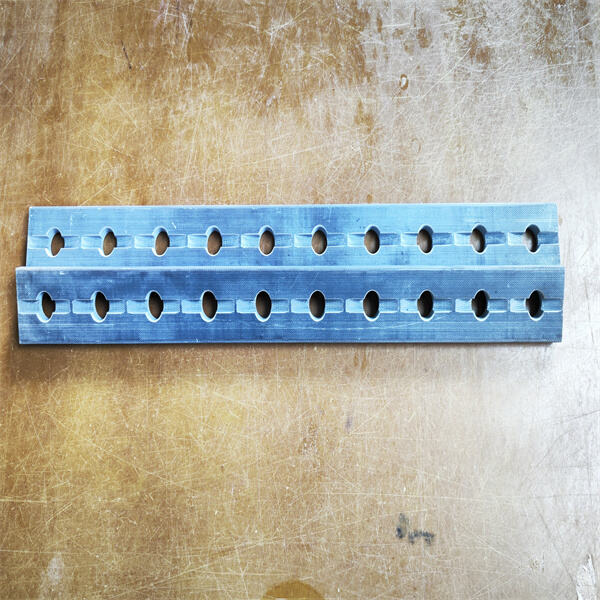

Fiberglass is a strong, durable and available for many projects. When fiberglass is combined with plastic, it increases in strength and utility. This particular composition is called fiberglass reinforced plastic, or FRP for short and it has a lot of advantages that will make you consider using this in many ways.

FRP-As per strucutural design it is very strong. Thus it achieves maximum celerity and efficacy also to this matter which results into advantage of eye; that is why, when constructed in walls floors-roofs they become a strength structure. FRP is a good choice for many builders and construction workers instead of using traditional materials like wood or concrete. One reason why is because FRP weighs much less than these materials, and that makes it easier to use. Using lighter materials will save time and energy as they are easy to carry.

FRP is incredibly durable, which is another reason why using it in construction makes so much sense. It does not rust or wear out quickly to any other materials. This allows it to be used in outdoor buildings that need different weathers such as rain, snow or sunshine so using a sturdy material like FRP is best when you want them not only safe but also last long.

Transportation : FRP is also a superior material for transportation. It is lightweight — this it biggest advantage. This weight-savings can help to save fuel and cut emissions by making vehicles lighter, too. Which is great for the planet and also helps people cut back on gas costs.

FRP is strong so good to support parts of the vehicle that have a short life span as well. This is in part what makes it so useful for materials like truck beds, where strength matters most, and the hulls of ships that constantly encounter water. FRP is even suitable for producing airplane components; they must be light enough to allow the plane efficient flight while being robust enough not to fall apart repeatedly.

FRP is also used in the construction of boat hulls, which come into contact with water. Since FRP does no rust, it can prevent boats from being damaged and therefore protect them for a longer period of time. Moreover, FRP is also applied in a vast array of boat components like soft chairs, cozy cabins or the tall masts carrying sails.

Over the years, we have observed that FRP is being widely used in industries itself. The prices come in at only 15-60% of what traditional materials like wood, concrete and steel cost. Having a cheaper material allows companies to remain competitive in the market and focused on creating premium products.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.