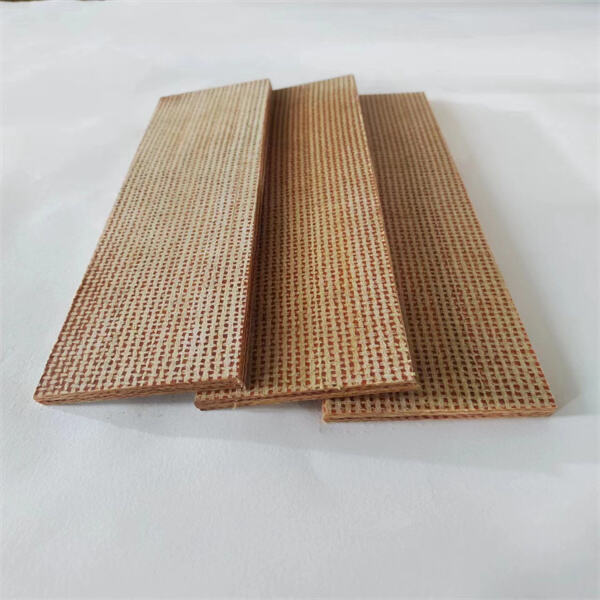

SMC composite stands for Sheet Molding Compounds. You may be wondering what that means. Well, these kinds of materials are made from combinations of various fibers including plastic and glass fibers. They are fused together to create something unique and powerful. When this mixture is heated and pressed, we create some sort of a solid and resistant board. This is a design you can use in several ways, which makes it very adaptable and useful.

SMC composite materials are also super strong yet lightweight, which is a massive plus. This matters a lot as they are excellent for things where weight makes a huge difference. SMC composites, for example, are used in planes, cars and even sporting equipment such as helmets and bicycles. Because they are strong and light, they are part of making these things safer and more efficient. These materials also have high impact resistance, so they're ideal in situations where things might clang or collide — like in cars or sporting goods.

Because SMC composites are easy to shape and mold, they suit many different product designs. This also made it great for designers and manufacturers seeking to produce customized products. They are also very strong and durable which makes them great for creating long-lasting quality products. Additionally, SMC composite materials can be quickly and easily produced, making them ideal for high volume products. In a fast-paced world, this efficiency can help organizations save time and money, which is invaluable.

It is the various advantages of SMC composite materials that make them so useful. They have a wide range of uses in multiple disciplines, making them highly flexible. SMC composite materials can be used in several industries like automotive (cars), aerospace (airplanes), and marine (boats). That means they are instrumental in helping to produce products that we use on a daily basis.

They're resistant to heat and wear quite well, so they're good for use in rough environments where feel could not last as long. Since they are also chemically and rust-resistant, they can be used even in places where they could easily get damaged. SMC composite materials can be molded into different size and shape due to their properties which makes them ideal for a wide variety of applications.

SMC composites can be altered and tailored to meet unique product requirements, making them ideal for developing new products and meeting customer needs. This means makers can make things that are just right for what people want. They can also be mixed with other materials to improve a product’s performance, or make it lighter, and that is always a big plus. Also SMC composite material is recyclable, making it a more environmentally friendly option since it reduces waste.

SMC is used in a variety of products, including cars, boats, and sports equipment. They also work great for making parts that have to survive harsh conditions. More specifically, components created with these materials can endure hard impacts, high and low temperature, and even some chemical exposure. Additionally, SMC composite materials feature easy processing, ideal for rapid, cost-effective, and high-quality product development.