This is a type of fiberglass and it known for being strong, so you better have very heavy files to get this at all seasoned one time or another. It is made by sandwiching layers of fabric and a tacky resin. However, this process makes it high strength and hard which is why several industries prefer to use carbon steel. Moreover, FR4 G10 is a lightweight material so you can easily take them anywhere and start working on it which also helps the builders to choose this type of raw materials for their projects.

One of the more important properties FR4 G10 is its heat and moisture resistant nature. This makes it great for use in hot and wet climates, like circuit boards and electrical parts where things can get super heated. This ability to withstand heat prevents the electronics from being destroyed. FR4 G10 is also resistant to all sorts of harsh chemicals so you can use them in any kind of factory setting where lots different substances are used on a daily basis.

Since FR4 G10 is versatile and so strong, it becomes ideal in many engineering applications. A popular application of FR4 G10 is the manufacture of printed circuit boards, or PCBs. This board is lightweight, but strong enough to take the pressure and heat. It allows our day to use devices (such as computers and mobile phones) can be running stably, much by the FR4 g10.

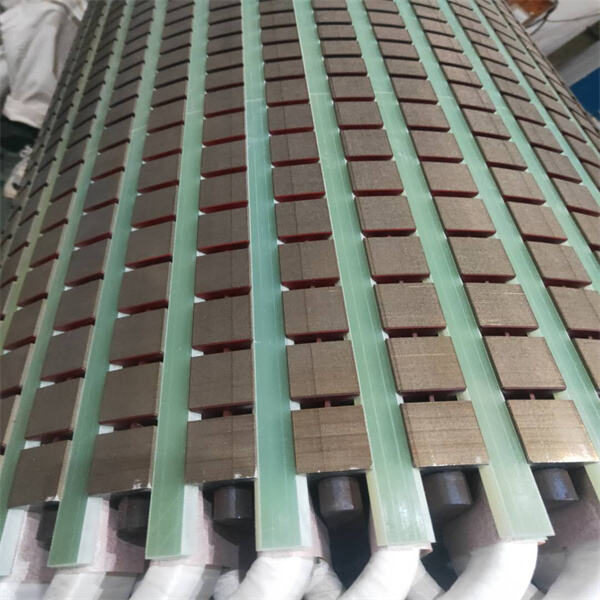

FR4 G10 is also used in the erection of wind turbines which is an important utilization as well. One example is wind power where FR4 G10 can provide the tensile strength that these structures need to survive intense winds and other environmental stressors. Even more over, FR4 G10 is widely used when it comes to aviation and marine jobs because it can insulate with high temperature inside air along side armed practicing facilities therefore surrounding a significant area of our protection as well technology.

FR4 G10 used in aerospace and defense One of the most exciting applications for this material has been within the U.S. Aerospace Industry. Its high strength and toughness is also used in the construction of military aircraft, such as those from Eco-composites. But the kind of materials required for aviation have to be resilient enough, and FR4 G10 is an apt material.

FR4 G10 is an exceptional material that has the potential to revolutionize how many cast and build items in a variety of industries. Employing FR4 G10 would enable companies to manufacture a more robust, durable and reliable product which could withstand harsher conditions. This technological evolution is changing the way our daily consumer goods are developed.

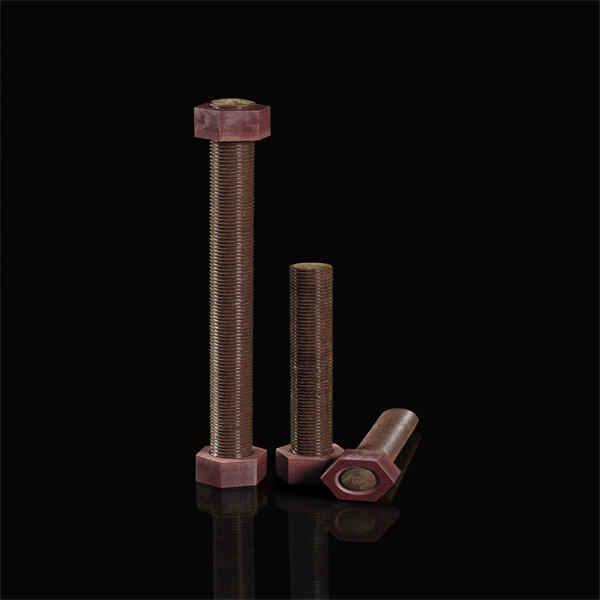

For example in the auto industry, FR4 G10 is a widely used material for fabricating components such as brake pads and steering. We rely on these parts to ensure that we are as safe and secure as possible when behind the wheel. FR4 G10 in medical, such as the production of various delicate instruments and tools shaped its safety and reliability personnel to meet strict standards for use by patients.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.