Fiberglass however is exceedingly difficult G11 Fiberglass It is also used in many other areas, such as in planes, boats and cars. You could also find it in a sports equipment you play games with. Continue reading to see what G11 Fiberglass is used for in various industries!

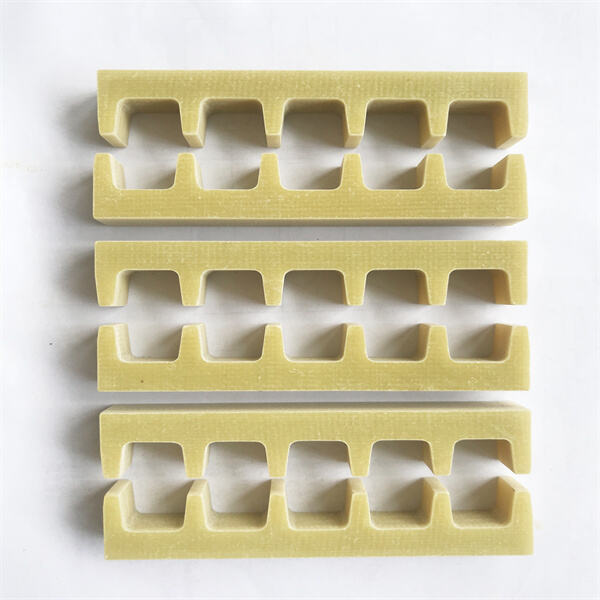

This is great for factories we add a lot of G11 Fiberglass, because it can be strong and longevity. G11 Fiberglass is widely used in factories to produce various kinds of parts and tools that are integral for operations of machines. It is also used in flexible screens and circuit board — the brains of electronic devices as it can withstand high heat without denaturing. This makes G11 Fiberglass a versatile material for many different factory jobs.

Aerospace — noun something, as an airplane or missile, designed for the air. Aerospace engineering loves G11 Fiberglass because it is so strong and can take the heat from all that flying high. G11 Fiberglass is used by the Engineers to manufacture essential parts like wings, rockets part and other core spacecraft items. It is to make sure that these flying machines are safe and aerodynamically sound, as they soar above the endless sky.

Boats and cars (renaing or if you still need help) are both forms of transportation, which also use G11 Fiberglass. Larger in mass than a true sports car, it is well-suited for these behemoths since it adds some strength to their makeup against corrosive sea air and other adverse elements. G11 Frp is normally used for the main hull or bottom of a boat and vehicle bodies. These also have to be extremely durable and strong so they can keep anything sparks out inexplicably exploding into a fireball.

Even without knowing it, you might have played with G11 Fiberglass right under your nose in sports such as baseball or hockey! It is this based material that we use to build hockey sticks, baseball bats and many other sporting goods; due its stiffness properties with added benefit of high tensile strength. G11 Fiberglass is what athletes consider a high impact industry, because their success depends on speed of movement and delivering blows during games.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.