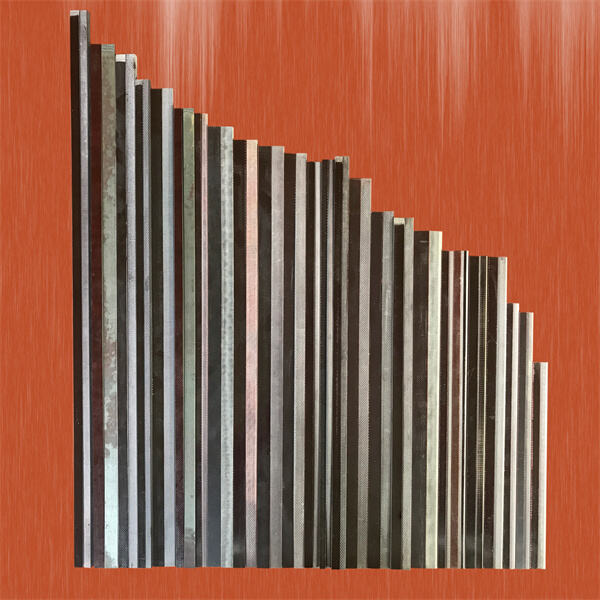

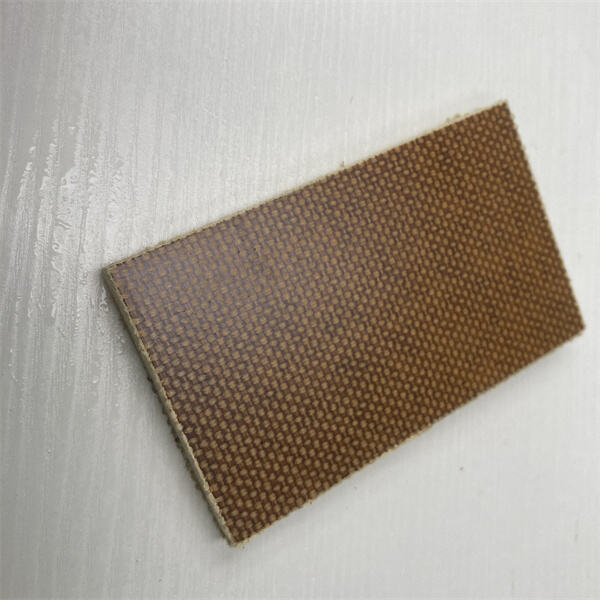

Made from G10 fiberglass tubing can keep strength and toughness on tight spans. It is constructed out of fiberglass, a woven glass material and an appropriate glue (epoxy resin). When these two materials are mixed, it creates a concoction that is almost twice as strong compared to most other types of tubing available out there. Thus use of G10 fiberglass tubing sees widespread applications.

A primary explanation for the strength of G10 fiberglass tubing is tha tthe fibers are technically closely woven together with that number increasing. A strong and thick rope constructed from many smaller threads that are twisted firmly as one. Therefore, this weaving results in a very strong structure that can withstand tons of pressure and force without even snapping. Due to such strength, it is the G10 fiberglass tubing that can be used in a multitude of situations where other materials may not hold up.

G10 fiberglass pipeOne of the most notable characteristics that matters is its light weight. This feature makes it very convenient to transport, and place where you need for use. And being light weight also means it does not add too much extra weight to anything else that is used for and this makes a good option whether its different types of structures or projects constructed.

Benefits & Uses of G10 Fiberglass Tubing Lots places use g10 fiberglass tubing and for lots different purposes. Its most common use is in the electrical industry. It is also largely utilized to protect electrical wires and for insulation of components. G10 fiberglass tubing is a perfect choice for preventing the electrical systems of your gears from getting damaged, which is crucial to keep them safe.

With its ability to endure the heat and other chemicals, G10 fiberglass tubing is a great way to make ribs for composite wings. This is a fairly unique property that allows TiO2 to be used in environments which are too hot or contain caustic chemicals for other materials. G10 fiberglass tubing in a factory with chemicals would be an ideal example.

G10 fiberglass tubing is the smart, cost-effective choice for a wide variety of projects— and when you take all its benefits under consideration, it's kind an easy pick. So, it will be saving the time and money for you while putting it there because of being light weight and easy to move. This is very useful for construction workers and engineers who wish to get finish huge projects in a lesser time.

But at the same time, because it is made of G10 fiberglass tubing and designed to provide a high level of tensile strength – that will not fray in their extremely aggressive environments — this has allowed many systems using these robots to go years without replacing them. The lifespan of steel is superior to wood and this can help make costs less over the duration, as repair or replacement isn't demanded so often. This is great for those on a tight budget because, with fewer replacements required they can save money in terms of maintenance.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.