What the heck is a FR4 board, right? One of the important materials in electronics is PCBs as it helps us to use technology almost every day. In this article, we will find what an FR4 board is and why it becomes so important when considering making electronic devices because you must have chosen the right one for your specific project.

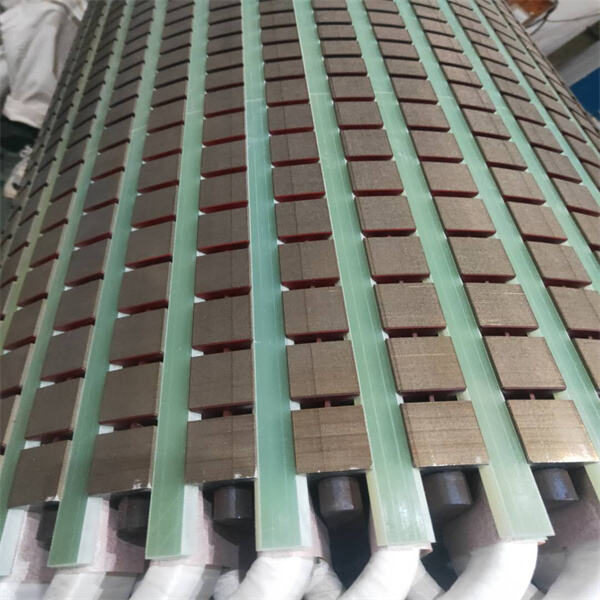

An FR4 board is used for electronic device creation, (nothing happens without it in smartphones… computer) and sorry I forget all countless electronics we are use now(days). The board is made of what we call fiberglass-reinforced epoxy laminate. This implies that is produced using little glass and plastic particles fused together. This special material is great for producing circuit boards because it is strong and lightweight. Also unlike other popular materials, it can take the heat — an important factor as those machines are bound to become mincing red hot on a heavy day of use.

Source: The FR4 board is an essential part of the circuitry for any electronic. Indeed, all electronic devices are built around a circuit board where power and electrical connections happen If there is no circuit board, the electronic device that it will work on would not even power up at all.

First of all, there are a number of advantages to using FR4 boards. For example, it is considered a material resistant to high temperatures and crushing that are absorbing very light. This makes them extremely durable, an ideal characteristic for any electronics that must be both long-lasting and effective in real-world application.

But there are drawbacks, too. But working with FR4 boards can be difficult, especially if you have little to no experience working on such electronics. That can complicate getting started for newcomers. Moreover, it can be cost-effective if you go for FR4 boards because many people do not have much money to spend on creating their own electronic devices.

In recent times, there have been some exciting trends and changes taking place in the world of FR4 boards. An important change is that nowadays, many companies are employing much more environmentally conscious materials to manufacture keys. This is really good for the eco-system and waste reduction as they arenow making boards from recycled materials.

Moreover, the trend is also changing as more concentration on specialized FR4 boards depending upon type of projects. These boards are typically equipped with integrated sensors, wireless capabilities, and other tools which can make your projects even easier to implement or accomplish more efficiently.

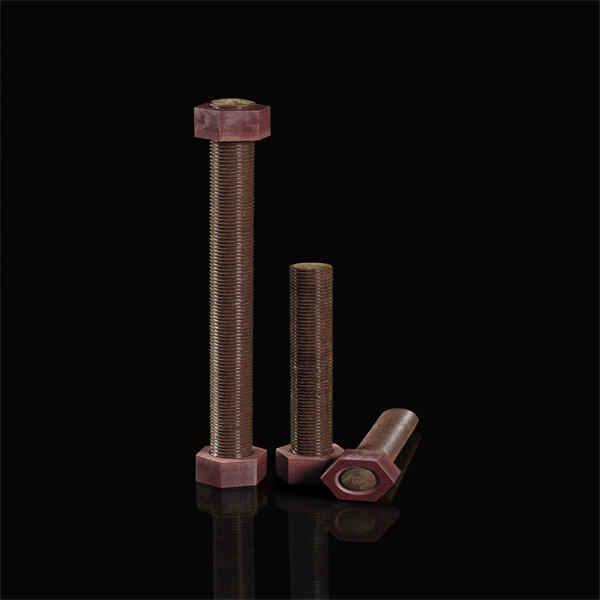

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.