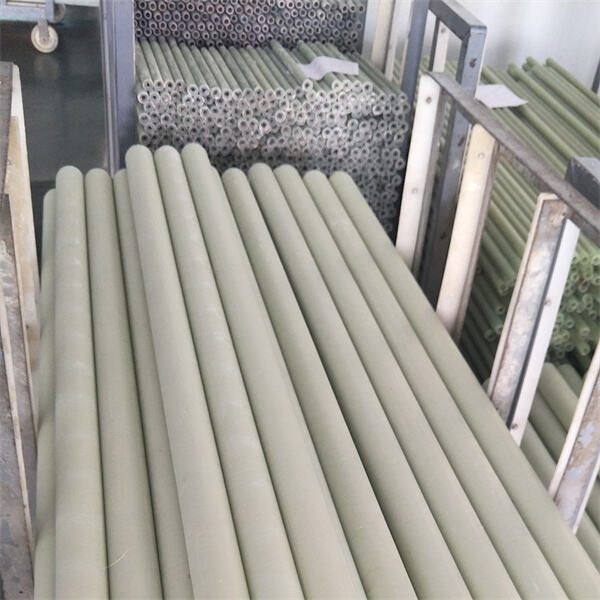

A glass fibre tubing is the type of tube that actually serves a thousand and one different purposes. This tube is built up of an amazing material called glass fibre, small little bits of glass which have spun into yarn. Strands are limited threads weaved into strengh with those small pieces. Glass fibre Tubes – Strong, light-weight and long lasting This is exactly why they are so valuable for a plethora of things like construction works, products and especially in the domains related to aeroplanes and cars. Today, we are going to tell you why glass fibre tubes so brilliant and what is its impact on our planet.

There are many good things about glass fibre tubes, which is why so many industries relish the opportunity to use them. For one, they are super tough meaning that high pressure and hot temperatures do not scare them. This puts them much ahead in the competition of some other stuff such as plastic or metal. As an example, glass fibre tubes can work fine when it becomes really hot or a heavy weight on them. They are also extra lightweight making them very mobile and changable. Construction is no exception, and it becomes all the more difficult when you have to move heavy materials around. Moreover, glass fibre tubes are rust-proof too so these will not get any damage in a short span of time and you would not need to clean it properly or change them again. But it also means they can be a cost-effective option for builders and manufacturers looking to produce goods of high durability.

The glass fibre tubes are applied in varied realms of the construction and fabrication sector. They may be applied, for example, to develop critical components for aircraft, marine vessels and automobile parts. In construction, these pipes reinforce the building and bridge structures — cellotex tubes in fact strengthen buildings once mixed with concrete. This results in stronger buildings built to bear more weight and last longer. Wind turbines are supported by tubes out of glass fibre, too. That is wind mills are mounted on these large scale blades that catches in the air to genererate electricity. Glass fibre tubes are so useful and this is what makes it a favorite across very many industries.

Glass fiber tubes play a very important role in the aviation and automotive industries. They help to make products that have to be lightweight yet strong, such as parts for airplanes. This is important because airplanes fly in harsh conditions, from high altitudes and extreme temperatures to mountains of pressure. In automobile factories, glass fibre tubes are used in the production of automotive parts such as car,trucks or buses. The fact that they are lightweight cuts down on the amount of fuel required to move around, which in turn saves both your wallet and nature alike. Moreover, they make the car durable and able to bear high pressures which makes sure that passenger is protected in case of an accident.

It is worth to mention that glass fibre tubes are not only useful, but also they are environment-friendly. There is one thing that makes these even more appealing to help our planet. For starters, they are composed of recycled materials such that in their production there is lesser pollution compared to other materials used. This is crucial as less pollution would prevent anymore air and water polluting. And, unlike with plastic tubes glass fibre cameras can last for ages (at least the ones I've used), so it is not like we have to throw them out every other day. Thats a huge win for our planet. In the end, glass fibre tubes can be used as a raw material to create new pieces of products and they ca recycled when these tubular components are no longer useful — perfect for environmentally conscious construction and manufacturing practices.

The future of glass fibre tubes Glass Fibre Sticks the next season can only get better! Scientists and engineers are constantly working to produce lighter, stronger tubes than those produced currently. The new enthusiasm is likely to translate into more money and effort for everything from faster cars, planes and wind turbines. It might only be a matter of time, as potentially one day glass fibre tubes being in hospitals and medical facilities for tools that are used by professionals with their everyday work/medical practices or even like prosthetics to help people. These tubes have endless applications and will be a significant component for wider innovation and technology in years to come.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.