If you look around in your daily habitat, most of the incredible machines and tools are busy doing their work for us. A lot of these machines require a type right here and there named as precision parts to operate adequately. These parts make the machines and tools run in an extremely smooth and synchronised way. They are produced by companies that specialize in creating precision parts. They are built to tight specifications using special "fitting" machines. These parts can be made from a variety of materials including metals, plastics and others based on what the part has to do.

Because each one has a role, it is very important to make the right part only for that machine. It is so because it enables and provides companies to manufacture parts that are the correct form, size and shape for an array of machines. The precision is the area most companies look for, when getting this kind of parts made and they have to use different resources; such as programs or machines to do them. Also, many of these companies operate in a very close-to-customer environment. This alliance ensures that they manufacture the correct part with compatible materials to aid proper functioning of parts.

These companies make parts that have to be accurate, strong and must last. For doing this, they adhere to stringent quality inspections that perform purposes checks & reviews during the manufacturing course. They also play an enormous part in the functioning of parts, if a piece is damaged or not built properly it can result in massive problems such as but not limited to machines breaking down and malfunctioning. Hence, it becomes essential for these manufacturing companies to ensure an extensive adherence towards quality control guidelines. By doing this, they guarantee that their clientele get the components from them which are in great condition and could be used for a long time.

Today with any new technology and addition in the manufacturing majorly now we see where ever it is being introduced (one good example will be CNC machine) have changed the whole industry. Furthermore, technological developments has allowed the manufacture of parts to be achieved with high dimensional accuracy and size as well as very complex geometry that was formerly unachievable. We should also remember the technology is not everything. Skilled and experienced workers who operate these machines are also essential. They are skilled professionals who can operate the machines efficiently, make up special programs for directing the machine and rectify any problem occurring during manufacturing process. These companies' success in creating quality parts relies on the mixture of their production capabilities with the use of state-of-the-art technology.

In the world of manufacturers, speed is king for every business and production of parts. Competitively, companies that can manufacturer parts simply at a faster pace have the edge. Then about 90 % of staff are able to work fast, hence this allows them in establish a good track record for the industry. Fast parts delivery means customers get what they need, when they need it. This just in time delivery helps to prevent problems and saves money on businesses part, as they are able to have their machinery without the wait. Hence, it is very essential for companies to play around their schedules so that they can meet deadlines and fulfil orders in good-time!

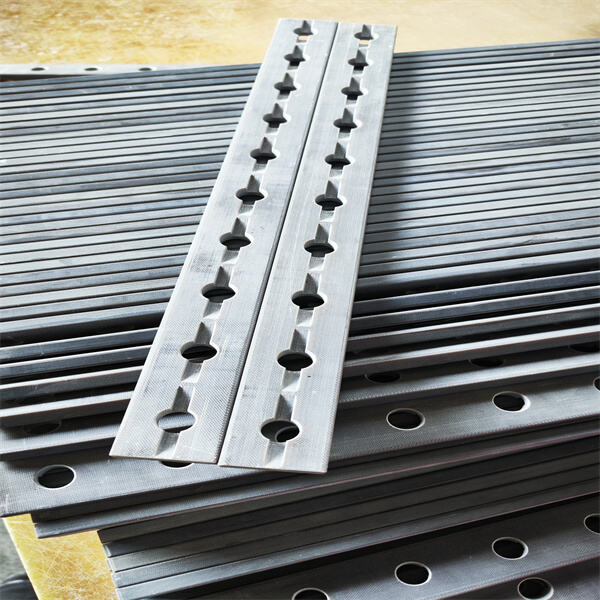

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.