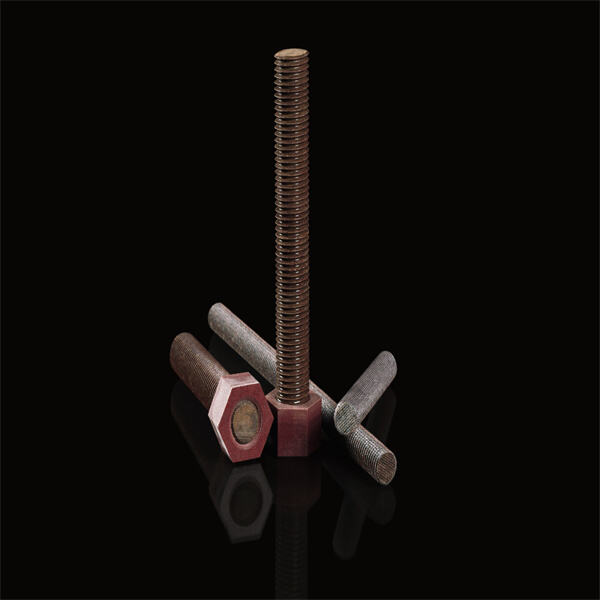

This is a specific type of material that you will find within many different types of businesses and industries which goes by the name phenolic paper sheet. It is formed by layering sheets of paper and bonding with a strong adhesive (resin). This process material is turned in actual quite fragile, hard / tough and which cannot easily break also damage. The phenolic paper sheets provide all these features, making it come in useful various ways.

Electrical Devices: Phenolic Paper Sheet is one of the most common uses. It is crucial for preventing electricity from escaping, which in turn helps protect devices such as transformers and keeps them functioning well. The materials are heat resistant and have insulating properties, which means they can stand up to high temperatures while remaining undamaged or breaking down. This hence makes it a good choice for electrical applications where safety and performance are prime considerations.

It is also used for creating high – pressure laminates including the phenolic paper sheet to develop strong sheets. Due to this feature these laminates are used over a large scope which includes flooring, furniture and kitchen countertops. These papers are then layered together with another material, usually wood or plastic, and put under very high pressure to create the laminates. The results is a very strong long lasting product that also looks great.

About Phenolic Paper SheetOne of the excellent features about phenolic paper sheet is its durability and strength. With high wear resistance and the ability to stay looking great, even on some of those most demanding projects. This is a material that you can find almost anywhere from factories all the way to DIY home projects and everywhere in between, which speaks volumes about its versatility.

Since phenolic paper sheet is an exceptional material it has countless uses, something that brings interest rate of a couple of businesses and fields. Indeed, everything from kitchen counters to floors can be made using concrete that is eco-friendly thereby making it increasingly popular among many in the construction industry. Phenolic paper sheets: This is how it's first employed in the automotive industry, as this stabilizer material is very tough and can take a beating.

They are also used in the aerospace industry to make parts for aircraft and spacecraft. This also makes it an ideal material to use in these important applications as its resistance from heat and pressure is high. It is a popular pick for essential pieces due to its resilience and sturdiness.

But there are a few things to consider when handling phenolic paper sheet. Cutting and shaping a thick material would be hard. That can be kind of annoying when a bit more complex projects. Another downside could be that this material is not extremely flexible for use like other materials might, so flexibility may become a problem depending on the situation it was used in.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.