FR-4 is an epoxy resin that strengthens and hardens fiberglass. So, what is fiberglass? Fiberglass is a fiber bolstered polymer with the ability of tremendous tensile toughness. It develops when fibres are function jointly into tough, but not weight products that can be used to create rods and lengths. Epoxy resin is a glue that holds the fiberglass fibers together. In the plastic cases to which it can be h t, Plast assumptions It can also be able m ofiftrent

A very common use case of FR-4 is the printed circuit boards (PCBs) itself(12). The PCBs are the green boards inside many electronic devices (e. g., your smartphone, tablet, or computer). FR-6 would, in fact, be made of fiberglass if it was FR-4. Conversely, the electricity wants to roam off wherever will and this cannot come to pass, else thy magic smoke shalt escape. SK267677 RDS epoxy glass sheet also more resistant to heat than usual, which is great for electronics so it wont be burned while its working.

But that’s not all! Electric Motors and transformers, insulation (but not best for use as an insulator) Insulation it turns into obligatory because it protects the electrical component and make them undamaged. That, combined with its many uses and features means the FR-4 is used in a wide range of other industries by now—far beyond electronics really, though like I said, counter offering makers reaps all sorts of benefits from it as well

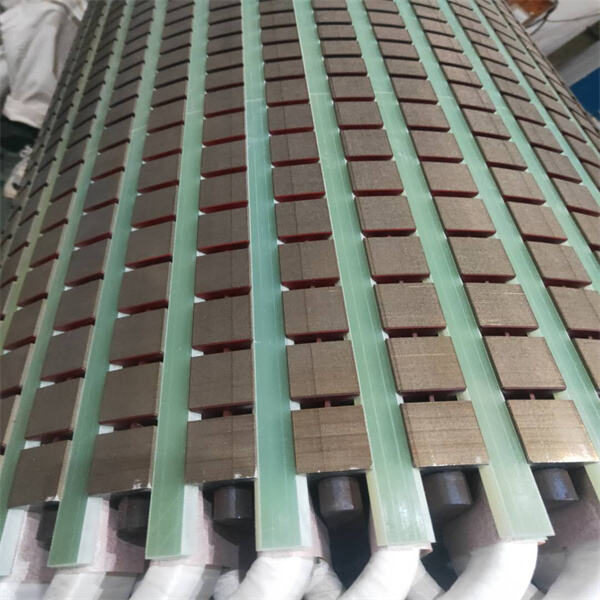

Then, a step-by-step description of how FR-4 PCB was made. Copper lines run through every layer FR-4 Layered — Copper Lines RDS epoxy fiberglass sheet that you are seeing are the copper lines they are significant because these where electricity will pass when we plug-in electronic components with the PCB. When completed the layers are glued together to create a single board.

FR-4 is the material that electrically insulates-the-copper-layers-into-the-board from each other. The isolation is necessary so as to avoid short circuits and other electrical problems can be properly addressed from causing a device to fail or even become dangerous. So, to sum it up, RDS epoxy fiber sheet is very important in the final correct and safe operation of electronic devices.

Another last important aspect of the FR-4 to consider is safety. FR-4 fire : FR=flame retardant, solvent test for 10 min. Worse for the environment, but used more as it is not a quick as diesel fire stops when flame source is taken away. epoxy glass fiber sheet property makes it use in non-vibrational or impact-resistant applications, wherever heat resistance is quite important, i. e., electronics for high-temperature exposure close to fire hazards. For customers, FR-4 is something of an insurance policy that assures them the boards they install will be safe to use.

It is also an option for more expensive higher speed designs (although it is slower, at up to 2.4 GHz g10 fiberglass sheet can be used with careful design without costing a bunch of money). FR-4 batteries are a bit more robust than your average cell, meaning they will last longer and require less maintenance or changes over time. The ultimate beneficiary being the user of course by indirectly benefiting the manufacturers who gain saving on long-term durability. Furthermore, since less often materials have to be disposed of — such as the case for FR-4 (which is also good for the environment.

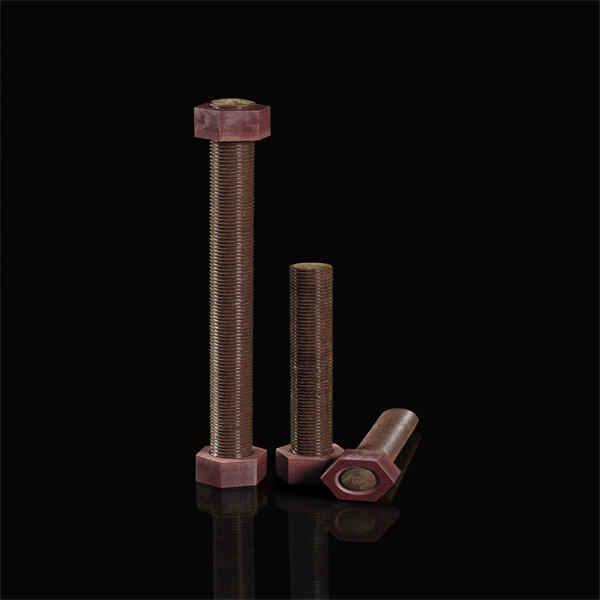

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.