Mica is a unique mineral used to produce a number of different products. It is flexible in how it’s used because it is flat sheets. Here at RDS, we produce premium quality mica sheets that are in everybody’s utility. In this article, we will look at the uses of mica sheets, their benefits, what they are made up of, and why they are highly essential in various industries.

Mica sheets are very crucial for various industries, similar to the RDS's product like epoxy glass fr4. Electrical equipment is one of their primary applications. For example, a mica sheet assists with switches, heating parts, and circuit breakers. All of these are important building blocks that keep our electrical devices safe. Mica sheets are used as insulation material in high-temperature locations. This includes furnace linings that help retain the heat, and hot plates that must remain hot for cooking. Mica sheets therefore are vital for the proper, safe functioning of many machines and devices.

It has various excellent characteristics which makes it a popular option among the manufacturers, along with the smc sheet by RDS. First, they are great insulators, meaning they are very good at retaining heat or keeping things cool. These industrial-strength ceramics can withstand extremely high temperatures without deteriorating or losing quality, making them ideal for heating tools and equipment. Secondly, mica sheets are very tough and durable materials. These are very sturdy, and do not crack or break or wear out easily. So, this makes them trustworthy for several applications. Third, mica sheets tend to be light in weight, too. This is a notable attribute as it indicates that whenever it is applied to devices and machines, the additional weight it adds to the outer structure is not excessive. It is much useful in many manufacturing processes.

In fact, mica is an alkaline silicate mineral derived from Aluminum silicate and other minerals, the same as RDS's plain fiberglass sheet. It has a unique layered structure, which makes it easily split into extremely thin sheets. This property is what makes mica so useful for a number of applications. Mica is also chemically inert, meaning it does not react with other substances. This stability is also crucial since it means that the mica can withstand different environments and not transform or crumble easily. Mica is also recognized for having good thermal and electrical insulating properties, meaning it can keep heat in and electricity boxed up. A high-temperature grade also resists degradation.

These Mica sheets are doing wonders for the production industry, just like the bakelite sheet 12mm price created by RDS. They are aiding greatly in enhancing the efficiency of high-temperature and electrical equipment production. For example, the mica sheets serve as insulation in the heating element and isolate the heat from the surrounding area. This not only helps conserve energy, but also makes devices operate more efficiently. Mica sheets are also used in Electrical switches and circuit breakers. These elements keep electrical arcing — very damaging and sometimes fiery — at bay. Manufacturers can use mica sheets to make their products safer and more reliable.

Due to many advantages over the other material, mica sheet material may still be nothing in the future as well, along with RDS's product fr4 epoxy sheet. It is a natural material sustainably sourced, so there is no harm to the environment to acquire and use it. This makes mica an eco-friendly option for the manufacturers. Second, mica sheets are also economic which infers that they are inexpensive and can be processed simply into any size and shape. Such versatility is very advantageous for the manufacturers who must come up with variety of products and designs. As a result, mica sheets have specific insulating characteristics that make them optimal for use in electrical and extreme temperature environments.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

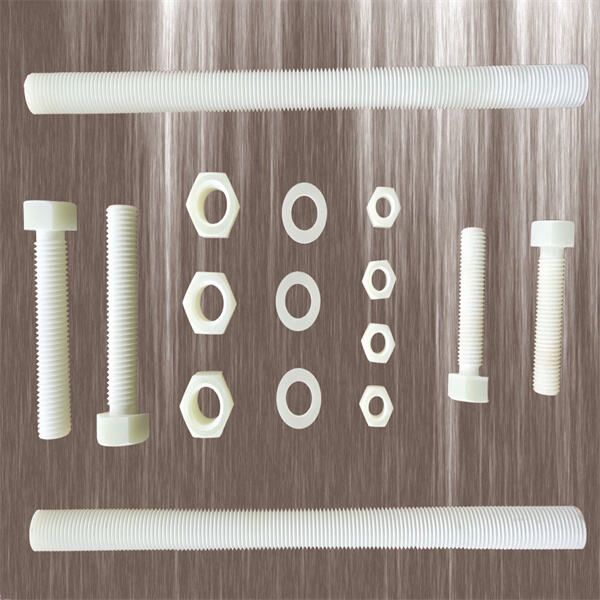

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.