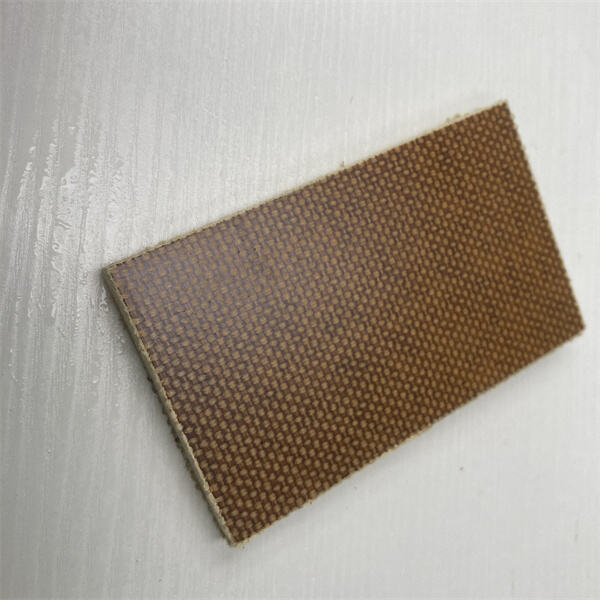

SMC sheet: SMC (Sheet Moulding Compound), this is a special material used in the manufacture of various products for many different industries. This is made of something known as Sheet Molding Compound. It is a mixture of different substances which gives corporative effect in making the sheet strong and versatile. A lot of the times, folks would like to compare an SMC sheet with regular plastic but it is very much not one and should be treated as such. SMC sheets offer a lot of benefits and are versatile in terms of usage.

Sheet Molding Compound, or SMC for short is the special material used to manufacture many parts and pieces needed during manufacturing. It is made of a composite resin, fibers and various other materials. SMC, because of this unique combination is typically more tough and stronger than alot of plastics. This makes it an ideal option for industrial use, as strength and long life are the main concerns here.

The major advantage of SMC is the ease in which it can be formed into myriad shapes and sizes. Its malleability makes it extremely useful for a whole host of functions. SMC is also very impact-resistant and does not rust or corrode, even at high temperatures. This makes it an ideal option for a variety of applications including many industrial situations where product resilience is essential.

Using SMC sheets in manufacturing can be a really good alternative. The biggest plus point of SMC is that it very lightweight even so much as being stronger than most man-made mater(iParaments. Like this, it is excellent for creating car and industry machine parts. It is also cost-effective, making it the first option for various industries in need of quality materials at an affordable price.

SMC sheets also are very friendly to work with. They can be molded in tons of different configurations and sizes, which is why manufacturers use them to make so many parts for all sorts of things. Moreover, since SMC is durable and damage resistant, it can be reliably used in abrasive atmospheres without failing due to wear or requiring too much maintenance.

The most significant benefits of SMC sheets, in relation to other composite types consist that they are commonly relatively cost-effective. This makes them one of the popular choices for manufacturers to produce high strength and durable parts cost effectively. SMC sheets have made companies save money while still making high-quality goods from the best raw materials.

SMC sheets are also used in aerospace and defense. In this fields, they aid in the manufacture of light but strong parts for planes and other vehicles that work to be both energy efficient as well as with significant life. Due to this toughness, SMC can also be an ideal choice in challenging environments like on oil rigs and other marine equipment where the conditions may not only be tough but corrosive too.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

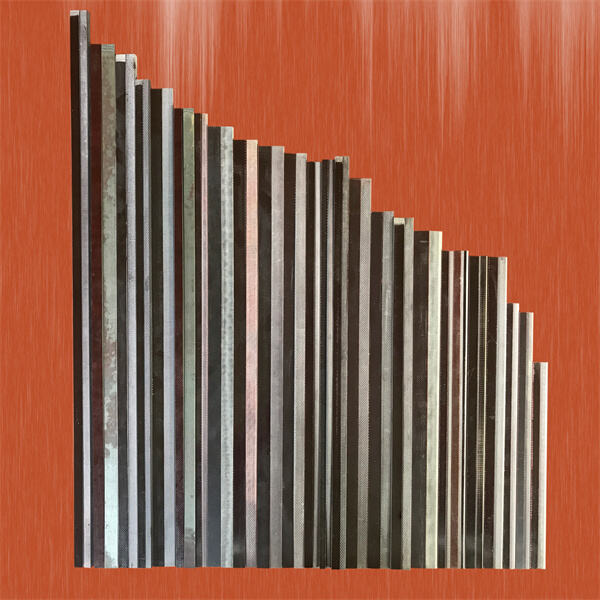

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.