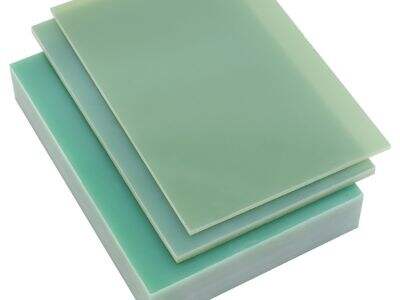

Epoxy fiberglass sheets, also known as Epoxy Glass sheets, are a durable type of laminate often used in electrical applications. They are especially critical when work is difficult and dangerous. These can resist high stress while not breaking. Many factories and electrical companies opt to use epoxy fiberglass in their projects because it is strong enough to withstand electricity and heat. They are also constructed from a set of glass fibers that have been combined with epoxy resin, which renders them incredibly rigid and strong. For hard working in high stress environments, quality materials are necessary. For these essential tasks RDS brings you quality epoxy fiberglass sheets that are perfect for the job at hand

Who Has The Greatest Wholesale Deals On Epoxy Fiberglass Sheets For Electrical Purposes

Companies are always looking for good deals on epoxy fiberglass sheets so they can save money and still receive quality products. Several suppliers discount their merchandise wholesale, so you can stock your shop at an even lower price. A great place to start looking is online. Websites that focus on industrial materials usually offer special sales or discounts for large orders. Do compare prices among different suppliers. In other words, a supplier may have a great price on one type of sheet, but another supplier might be better for the price on another type

Some outfits, such as RDS, may have special programs for the frequent flyer. Such programs could provide even greater discounts and bonuses for frequent buyers. You can also visit a local distributor. They might have stock of something sitting there now, so you wouldn’t need to pay for shipping just to get your hands on them more quickly. Many providers also have customer service representatives who can assist with any questions you have about which is best for your needs. Be sure to ask about delivery times. When you are in the zone on a project, quick delivery can be very important

Another thing to do is to search for trade shows or conferences. At these events, you’ll frequently find special offers and get to meet people from various companies. It can also help you to learn more about the products and connections within industry. It’s important to always read reviews, and check the reputation of a supplier before making a big purchase. This will help you sidestep issues down the road. In the end, a little homework can save you arm and legs for some of those epoxy fiberglass sheet deals to keep your electrical project on the straight and narrow

Why are Epoxy Fiberglass Sheets Great for High Stress Places

Epoxy fiberglass sheets are ideal for high-stress environments due to the fact that they are extremely strong, and resistant to nearly every type of damage. First, they can bear heavy loads without collapsing or cracking. That is particularly important in electrical work where there’s potentially a lot of tension and weight. Consider a worker who is attempting to install heavy machinery. If the materials they use are not strong enough to support the weight, it could result in accidents

The other reason for why these sheets are great is that they aren’t susceptible to heat. A lot of electrical work generates a high amount of heat that can ruin regular materials. But epoxy fiberglass is capable of withstanding high temperatures without melting or weakening. This makes it a convenient option for electrical panels or circuit boards that are required to remain cool and function well

Epoxy fiberglass sheets are also chemical resistant Rigid laminate insulating tubes FR4 Tubes are made from woven glass cloth combined with a heat-cured epoxy resin. In addition, some workers in electrical jobs may use cleaning solutions or other chemicals that are potentially damaging to regular materials. You won’t have to worry about damage from spills or leaks with epoxy fiberglass. That helps the materials last longer, which in turn saves money on replacements

Finally, these sheets are wonderful insulators. That means that they can turn off the flow of electricity, which is very useful in electrical devices. If electricity is able to escape, it can be a bad thing, such as shorting out or possibly even starting fires. Epoxy fiberglass insulation keeps everything safe. RDS makes sure that their epoxy fiberglass sheets adhere to these high specifications, which is why they are considered one of the best solutions for challenging electrical jobs

High-stress environments are safe and reliable for workers when epoxy fiberglass sheets are used. For heavy loads, heat, chemicals or electricity; these sheets are reliable

Epoxy Fiberglass Sheet Application in Electrical Work: The Most Commonly Used Way and the Use Note

Epoxy fiberglass sheets are durable and helpful, especially in electrical works which require safe application. But there are issues people commonly have when they use them. One major drawback is handling; the sheets can crack or break. This can occur if the units are dropped, or if something heavy is set on them. To prevent this from happening, always take care when handling typewriter correction sheets and store them someplace safe where they won’t be damaged. Yet another: It can be tough to cut these sheets. If they get cut without the proper tools, it can result in jagged edges or even break the sheet. To correct this, it is better to work with sharp instruments that are specifically designed for cutting fiberglass. This provides clean edges, and ensures the sheets will fit in any electrical configuration

Occasionally, people don’t realize they didn’t check the size of their epoxy fiberglass sheets for their project. If the sheets are too small, there can be gaps; if they are too large, they may be difficult to work with. To make sure you buy the right size of sheets, be sure to measure your space prior to making a purchase. Some users may even be unaware that not all epoxy fiberglass sheets are created equal. Various types of sheets have different heat and electricity ratings. If a sheet’s stress level isn’t high, it may not perform well in the kind of tough electrical work that we often do. To prevent this, only purchase sheets that are rated well for what you actually need

We, at RDS, will have you using epoxy fiberglass sheets safely and efficiently. Being cautious and attentive to the details will save you from some of the common problems and make sure your projects go as smoothly as possible

What to Look for When Buying Epoxy Fiberglass Sheets Wholesale

If you are buying in bulk, particularly of epoxy fiberglass, then it is essential that you know what to look for if you want to ensure the quality. Start by looking into the thickness of the sheets. Thicker sheets are generally stronger and more suited to high-stress applications, but can be heavier. You can get away with something thinner for a lighter cover, but I’d probably keep it fitting to the needs of your project. Next, consider the electrical characteristics of the sheets. You need sheets that insulate well (such as, are non-conductive, letting electricity pass through only slowly). This is extremely useful thing for electrical work to make everything safe

Also it is important to take note of the heat resistance of the sheets. If the sheets are going to be exposed to heat sources or will experience high temperatures, they should be able to endure those without melting, losing shape, or corrupting. Check the heat resistance of a sheet to make sure it has fireproofing technology. Also factor in the resistance to chemicals of these sheets. If they are going to be exposed to oils, solvents or other chemicals, make sure they can withstand that and not be destroyed

It’s also advisable to look at the sheet’s surface finish. A slick surface is preferable if you’re working with sheets that need to fit tightly together or you still demand a clean finish. If ordering from RDS, request samples if you can. That way, you can look and feel before placing a big order. If you consider these specifications, you will be able to choose the perfect epoxy fiberglass sheets for your electrical applications

What are the newest developments and applications in epoxy fiberglass high-stress sheets

There are many new and exciting things happening in the world of epoxy fiberglass sheets especially for high stress electrical jobs, Recent years have bought it to us! One of the greatest innovations is the fact that this uses state-of-the art materials helping these sheets be stronger and more robust. These new materials can make the sheets better at withstanding damage from heat and electricity than their predecessors. This can be highly beneficial during periods of extreme heat or at a time when there is a great deal of electrical activity

Another is an advancement in the method of manufacture. New methods provide a means to better manage sheet thickness and density. It also means that manufacturers like RDS can design sheets to perfectly suit their customers, whether they are in need of something lightweight or ultra durable. In addition, some new epoxy fiberglass sheets use special finishes that are scratch- and chemical-resistant. This is ideal for projects where the sheets will be subject to severe conditions

Another trend that’s fun to follow is the emphasis on sustainability. Many companies, including RDS, are developing epoxy fiberglass sheets out of composite waste. This is the environmentally friendly option, as it reduces waste. Added bonus: These sustainable sheets don’t have to forfeit the degree of high performance you’d expect from a standard set

Last but not least, even digital in mainly involved (as well as possible) for the epoxy fiberglass sheet. Companies are designing and testing sheets with sophisticated software before creating them. This can make sure that they work properly and are safe. It is these advancements that make epoxy fiberglass sheets for effective and reliable in high-stress electrical work, providing the user confidence in their repairs or projects

Table of Contents

- Who Has The Greatest Wholesale Deals On Epoxy Fiberglass Sheets For Electrical Purposes

- Why are Epoxy Fiberglass Sheets Great for High Stress Places

- Epoxy Fiberglass Sheet Application in Electrical Work: The Most Commonly Used Way and the Use Note

- What to Look for When Buying Epoxy Fiberglass Sheets Wholesale

- What are the newest developments and applications in epoxy fiberglass high-stress sheets

EN

EN