Galvanic corrosion occurs when two dissimilar metals come into contact with each other amid moisture; one of the metals degrades at a faster rate. In the case of pipes and flanges that can cause big problems like leaks or system failure. This is where flange isolation gasket kits become handy. These systems prevent metals from actually touching, thereby helping to thwart the corrosion. At RDS, we manufacture those gasket kits that protect your commercial machinery and makes it serve for longer. These kits are specifically designed to put a barrier between metallic to block the current that is causing such corrosion. None of it would be needed, because metals in intimate contact with each other can pool negatively charged electrons around themselves and create tiny electric currents that slowly eat away at parts. Using flange isolation gasket kits is a wise choice to protect your investment from the possibility of unnecessary shutdowns and costly repairs.

Why Flange Isolation Gasket Kits Are Worthy to Prevent Corrosion

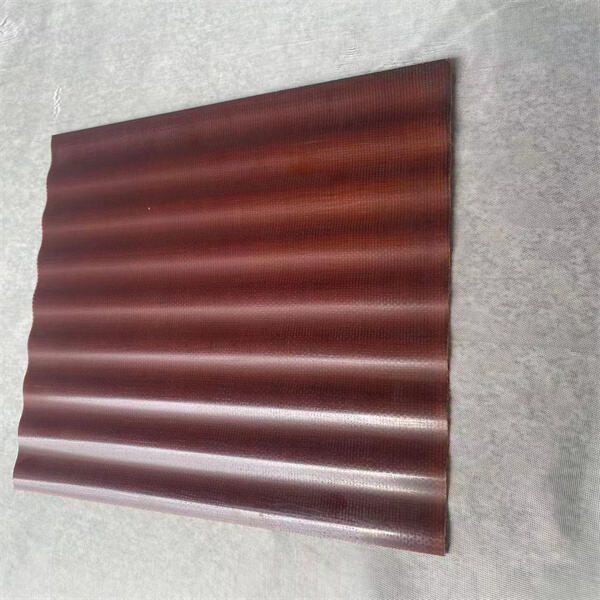

Flange isolation gasket kits are not regular parts, they are essential for the protection of metal joints in countless machines and pipes. At RDS, we understand the significance of thwarting corrosion that can corrode these connections. The kits contain special gaskets, sleeves and washers that work as shields. When you place them between two types of metal, they halt the electric current that is responsible for galvanic corrosion. Think of two friends who have trouble getting along and start fighting the moment they come into contact that’s what happens when metals cause corrosion. Our gasket kits prevent these parts from “arguing” and destroying each other. Plus, these kits are constructed from materials resistant to water and chemicals, two of the things that can accelerate corrosion. For instance, pipelines that transport salty water are more at risk for corrosion. Metals like steel and copper can go really bad without the proper isolation. But the reaction gets blocked with RDS gasket kits, effectively isolating. We’ve seen the life of our protected flanges lasting many years longer than unprotected systems. It is about not stopping corrosion: It’s about saving time and money on repairs. Plus, these kits make you safer too, corrosion can lead to leaks or breaks that are hazardous. Reality has shown us that a good flange isolation gasket kit acts like Armour and maintains the system healthy in all time. Despite the harsh environment, these kits get down to business and do so quietly but forcefully. Every so often, people neglect their significance until corrosion leads to a significant issue. The reason RDS is so emphatic about using these kits from the beginning is that they believe it should be a consideration from day one.

Guidelines to Selecting Reliable Flange Isolation Gasket Kits for Galvanic Corrosion Prevention

Not all Flange Isolation Gasket Kits are Created Equal. It can be kind of tricky to pick the right one, but it’s super important. At RDS we know from years of experience what makes a gasket kit effective. For one, the materials do make a difference. Well-designed kits are built with non-conductive materials they don’t conduct (pass) electricity. Good rubber or PTFE gaskets, for instance, are effective insulators of the passage of electric currents. Additionally, the sleeves and washers are to be constructed from an unbreakable, chemical resistant material. Wear those parts out quickly, though, and corrosion can creep in. The other significant factor is design. Kits that tightly seal and adhere closely around bolts and flanges with no gaps do a better job. Where there are gaps or the parts do not fit closely together, water may enter and cause corrosion regardless. At RDS, we delete test each kit to ensure that it all fits properly and covers every possible contact point. Installation is also important. But even the best kit’s not going to work if it’s not installed correctly. That’s why we offer clear instructions and provide support to help customers install kits correctly. Sometimes, others believe that any gasket will do, but the kit designed for isolation really does matter. For instance, if in a plant steel and copper pipes are connected by means of steel pipe flanges with the help of randomly chosen gaskets, this can soon begin to cause corrosion. But RDS kits prevent it from occurring. Finally, durability is key. Our kits endure rugged use for many years. They remain un-cracked and do not lose insulation over time. And that means less time thinking about maintenance, and more faith in your system. From our feedback, choosing a good flange isolation gasket kit is an investment in safety and dependability, something every industrial user will appreciate.

Flange Isolation Gasket Kits – Typical Problems & How to Solve Them

Flange isolation gasket kits are extremely useful when it comes to resolving an issue such as galvanic corrosion. This occurs when two dissimilar metals make contact and begin to rust more quickly due to an electric reaction. But sometimes, folks struggle working with those gasket kits. One frequent issue is that the gasket does not seat properly between the flanges. The flat parts where pipes connect are called flanges. When the gasket is undersized or oversized, it can allow water or air to seep around both. This renders the gasket less effective, as such the metals can still make contact, leading to corrosion. To combat this problem, it is critical to be certain of gasket measurements when selecting a kit. Starting with the right size helps the gasket to block the metals entirely.

Another concern is that the gasket materials may wear out too quickly. If the material isn’t strong enough to withstand heat, pressure or chemicals in the pipes, it will break down and lose its protective qualities. Once this occurs the metal components will begin to corrode anew. To remedy this, be sure to select gasket kits made of materials that can withstand the conditions in your system. And inspect the gasket at regular intervals for damage or wear and tear, replacing if necessary. This makes the protection remain effective.

On occasion, the gasket may not be installed correctly. If the gasket is positioned unevenly, or the bolts that hold the flanges are not tightened properly, then the gasket will not perform as intended. This can lead to leaks or cause metal parts to make contact. The best way to prevent this issue is by watching clear installation instructions with the proper tools. Investing time in installing the gasket properly helps it prevent galvanic corrosion more effectively. RDS advises that you always inspect for proper fit and the product’s security prior to use.

What are the Best Materials for Flange Isolation Gasket Kits to Keep Galvanic Corrosion away

The selection of suitable materials for flange isolation gasket kits is particularly important because not all materials are good at preventing galvanic corrosion. The gasket is a sort of barrier between two metals, so it must be strong and not let electricity through. Rubber is one of the best materials to handle this type of work, especially rubber compounds like EPDM or neoprene. These rubbers don’t conduct electricity and are very effective at closing the space between flanges. They’re also impervious to water, heat and many chemicals. That’s because they continue to work for a while to offer protection to the metal parts.

Another excellent option is a plastic known as PTFE, or polytetrafluoroethylene. PTFE is super smooth and slippery, so that helps the gasket fit perfectly and block off any leaks. It is also resistant to many chemicals and high temperatures, which means it is great for harsh conditions. When PTFE is included in a gasket kit, it’s what stops the electric flow between metals that leads to corrosion. At RDS, we incorporate premium PTFE into some of our flange isolation gasket kits because it works so dang well.

And then, also in addition to rubber and PTFE, some gasket kits have a thin layer of insulation material such as mica or fiberglass. These substances, which conduct no electricity at all, provide extra protection by ensuring that the metals remain apart. When you supplement these layers with rubber or plastic the gasket has a more potent ability to stop galvanic corrosion as well. It is crucial to choose gasket kits with materials tested for your intended use whether that’s the kind of metal pipes you’re coupling or fluid running through them. RDS has a variety of materials in our gasket kits to meet your particular needs and provide the best protection against corrosion.

Guide to Determine Correct Installation of Flange Isolation Gasket Kits for Optimum Corrosion Resistance

It is extremely crucial to install flange isolation gasket kits correctly to completely prevent galvanic corrosion. However, if the gasket is not properly seated, the metals again can come into contact or leaks may develop which would allow corrosion to begin anew. The flange surfaces must initially be clean and smooth to seat the gasket. Dirt, rust or rough surfaces can prevent the gasket from sealing properly. We always advise RDS customers to prepare the flanges meticulously with a wire brush or cloth, and ensure any old material, or rust is cleaned off.

Next, delicately position the gasket between both flanges. It needs to cover the entire area where the metal meets, not rise above it or leave visible gaps. The gasket is the key here, make sure you measure your flanges before buying the kit to ensure you get one that’s the right size. This should ensure you achieve that best seal on your gasket. Tighten the bolts in a special sequence when the gasket has been placed. Bolts are typically tightened in an X or star pattern to evenly compress the gasket. This prevents leaks and protects the gasket from damage. When the bolts are tightened too much or not enough in one area, the gasket may tear or fail to seal altogether.

You also need the proper set of tools to ensure that the gasket material kit is installed correctly. That’s where a torque wrench comes in: Use it to tighten the bolts to the precise amount of pressure required. This eliminates the risk of over-tightening, crushing the gasket which can lead to a leak or under-tightening, causing a leak. Have questions on the amount of torque to be installed tightening and the correct bolt tightening sequence? At RDS we include easy-to-follow instructions with our flange isolation gasket kits to ensure proper installation.

Lastly, make sure to inspect the flange and gasket for any leaks or loose bolts once everything is installed. This can help to identify issues in the early stages and protect the system from corrosion. Flange insulation gasket kits Insulating Gaskets prevent the flow of electrostatic charge to personnel who touch the metal components | cold shrink tube Proper steps must be following in order to make sure that galvanic corrosion is blocked for years with appropriate installation and maintenance of flange isolation gasket kit. By following these suggestions from RDS, you’ll enjoy optimal results in protecting your pipes and metal components.

Table of Contents

- Why Flange Isolation Gasket Kits Are Worthy to Prevent Corrosion

- Guidelines to Selecting Reliable Flange Isolation Gasket Kits for Galvanic Corrosion Prevention

- Flange Isolation Gasket Kits – Typical Problems & How to Solve Them

- What are the Best Materials for Flange Isolation Gasket Kits to Keep Galvanic Corrosion away

- Guide to Determine Correct Installation of Flange Isolation Gasket Kits for Optimum Corrosion Resistance

EN

EN