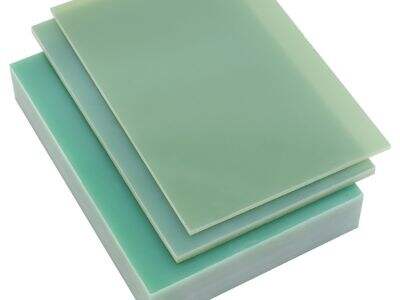

Key Application : Epoxy fiberglass sheet is an important insulating material for electrical appliances, it has good mechanical properties in the medium temperature. These sheets prevent electricity from going where it shouldn’t and wreaking havoc. Here at RDS, we produce these sheets with high attention and careful work to ensure that they protect the electronic components in well order. Epoxy fiberglass sheets are durable, nonflammable and do not shatter — all key requirements for high-voltage systems. They are also able to resist heat and moisture that would be begin to damage electrical devices. With these characteristics, RDS epoxy fiberglass sheets have been more and more trusted by machines and apparatus using high electric

Why Epoxy Fiberglass Sheets are Perfect for High Voltage Insulation

Epoxy fiberglass sheets can be useful for preventing electricity from jumping between components. This becomes highly critical in high-voltage systems where power is so great that a spark, or short-circuits could easily form. The epoxy part is a type of plastic that conducts electricity not at all. The sheet is reinforced with fiberglass, comprised of small glass fibers that give the sheet strength so it doesn’t crack or bend too much. Combine these two elements and the sheet becomes a strong, safe barrier. For instance, in power transformers or circuit breakers, these sheets prevent electricity from going where it doesn’t belong. The sheets are also very resistant to heat. When electricity passes through, it causes a heating effect and some materials become supple or melt. But RDS epoxy fiberglass sheets stay hard when it’s hot. And, they don’t absorb water or chemicals one of which could weaken them. This means they last long even in harsh conditions, such as in factories or outdoor power stations. So, they store electrical parts safely and work smoothly for years

What Are the Major Advantages of Epoxy Fiberglass Sheets for Electrical Equipment

Electrical Machines – The Advantages For Electric Motors and Generators There are many reasons why people use epoxy fiberglass sheets in electric machines, and there is a range of benefits that certain other materials simply can’t compete with. For one, they are quite lightweight but durable, so while they don’t weigh your equipment down or take up much space, it’ll still be well-protected. At RDS, we have witnessed just how maintenance costs can be cut with these sheets that refuse to wear out quickly. They also help prevent fires. Epoxy Fiberglass Sheet has high voltage resistant and no easily firing, so ideally choosing the perfect that can be reduced accident. Thats huge for the safety of your workers and to protect that very expensive equipment. Another pro is that they are easy to mold and cut to size. Whether it’s a little gadget or a big piece of machinery, these sheets can hug just right. We’ve cut a lot of custom sheets for specialized machines, and that flexibility ensures that customers get exactly what they want. Plus, the sheets don’t release any electricity. It prevents power loss and allows machines to run better and more safely. Machines that work better save energy and money. These are just a few of the reasons why RDS epoxy fiberglass sheets are an intelligent choice for high-voltage electrical equipment

Here Are Common Problems Encountered When Applying Epoxy Fiberglass Sheets For High Voltage And How These Can Be Prevented

The epoxy fiberglass sheets are most crucial components in high voltage systems. They help ensure that electricity is safe and operates effectively. However, people encounter issues while using these sheets in some cases. It is not uncommon for the sheets to be cracked or broken if handled roughly. High-voltage systems require tough materials because electricity can be formidable. If the sheets fail, the system could cease to work or become unsafe. This can be prevented by taking care of the sheets while fitting and maintaining the sheets. Make sure you have the right tools and try not to drop or bend your sheets too much

One other problem is that epoxy fiberglass sheets may soak up moisture if not stored correctly. If moisture gets in between the sheets, that can weaken the fabric. That can cause the sheets to be less effective at blocking electricity from leaking. To avoid this, sheets must be kept and stored in a dry environment that is sealed when not in use. Also, periodic inspections for any evidence of water damage are also a good idea

And sometimes people are working with or have wound up a sheet that’s not quite the right thickness or quality for their high-voltage application. Bad sheets that are thin or have low-quality materials cause electrical problems and burnout. You’ll also want to make sure you are using epoxy fiberglass sheets that are designed for high-voltage systems, such as these ones from RDS. These sheets are safety- and strength-tested

Use common sense (handling with care and storing properly) and select the right quality, and you can avoid most issues. This is what allows high-voltage systems to operate safely and over many years

Why are Epoxy Fiberglass Sheet Wholesale Preferred for Industrial High Voltage Projects

If you are involved in large industrial projects that have high-voltage systems, then buying epoxy fiberglass sheets wholesale is usually the most cost-effective option. Wholesale is buying sheets in bulk, usually at reduced price. This is good news, of course, because big jobs require lots of sheets and purchasing in low quantities can drive up cost and slow down work

These wholesale epoxy fiberglass sheets are favoured for its constant supply. Commercial developments are typically on tight timelines. And if the sheets run out in the middle of a project, it can lead to delays and added expense. Purchasing wholesale from a known supplier such as RDS also ensures that the project team can grab up all of the sheets they require in one hit, without delays for additional deliveries

Another reason is cost-effectiveness. Small batches are usually more expensive than wholesale. This saves companies money, and when working with large projects, this becomes important. The money saved can then be put towards other crucial elements to the project

Wholesale RDS sheets also have dependable quality. If purchasing in bulk from a trusted brand, your sheets will all be the same thickness, strength, and safety features. That makes it less complicated to design and manufacture high-voltage systems because engineers know exactly which materials they are dealing with. Consistency helps to ensure the whole system is safe and runs smoothly

Lastly, purchasing in bulk helps organizations have an extra set of sheets on the side. Backup sheets are a good idea, as damaged or installed incorrectly during installation. And with extras on hand, the job can proceed rather than waiting for fresh material

For this reason, wholesale epoxy fiberglass sheets are the best option for these industrial high-voltage projects, because time is saved as well as money and safety is always maximized

What Every Purchaser Needs to Know About High Voltage Epoxy Fiberglass Sheet Quality Standards

When purchasing sheets from epoxy fiberglass for the high-voltage systems, it's crucial for you to learn about its quality standards. Standards of quality are rules or tests materials must conform to in order to be safe and dependable. For high-voltage applications, these standards ensure that sheets can withstand powerful electricity without breaking or failing

One important quality attribute would be electrical isolation. Electricity can no longer flow through epoxy fiberglass sheets. This is an added safety feature which prevents shock or damage to machines and people. RDS sheets are meticulously crafted to exacting insulation standards. They are also tested to ensure they can withstand high voltage without leaking electricity

Mechanical strength is another important quality point. The sheets must be strong enough to support the system without breaking or bending. In high-voltage systems, parts are typically heavy or encounter sever forces. If the sheets are feeble, then perhaps the entire arrangement will fail. RDS sheets are engineered to be incredibly tough, meaning they last longer and maintain the safety of the system

Heat resistance is also important. High voltage systems can become hot during operation. They might melt or not retain their full strength if the sheets are not heat-compatible. Good sheets like RDS are tested to some decent temperature. That's because they are operational even as the system is heated

Buyers should also look to see if the sheets are certified by reputable testing organizations. DIN Certifications indicate that the sheets passed key safety and quality tests. RDS gives clear information on certifications, giving you the confidence to say that you care about what’s in your home

Knowing of these quality standards allows you to be picky when buying epoxy fiberglass sheets. Opting for sheets from a well know brand such as RDS guarantees materials that are safe, hardy and dependable in high voltage systems. And, above all the people and equipment are kept safe

Table of Contents

- Why Epoxy Fiberglass Sheets are Perfect for High Voltage Insulation

- What Are the Major Advantages of Epoxy Fiberglass Sheets for Electrical Equipment

- Here Are Common Problems Encountered When Applying Epoxy Fiberglass Sheets For High Voltage And How These Can Be Prevented

- Why are Epoxy Fiberglass Sheet Wholesale Preferred for Industrial High Voltage Projects

- What Every Purchaser Needs to Know About High Voltage Epoxy Fiberglass Sheet Quality Standards

EN

EN