GPO3 fiberglass made by RDS panels are tough and clever with electricity. These panels don’t just do the job for decades, they help ensure electrical systems work safely and smoothly. People tend to think fiberglass has everything to do with being tough or light, but it’s also about how it deals with electricity. We understand here at RDS, that panels need to be able to carry electrical loads and do so without giving problems. That’s why our GPO3 panels are carefully designed to ensure everything stays working the way it should, even when electricity is surging! We’ll see how these panels handle electrical power and play it safe

GPO3 Fiberglass Panels, What Are the Electrical Load Capacity Ratings

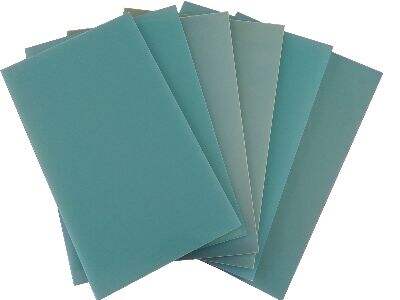

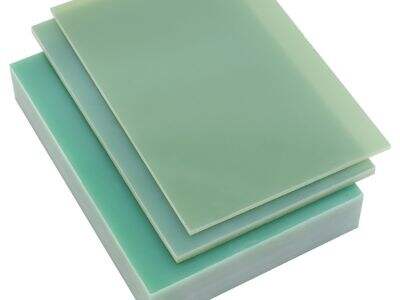

RDS GPO3 fiberglass panels can carry heavy electric loads. Electrical load capacity refers to the amount of power a material can safely carry without overheating or causing a fire. Our panels are constructed with special fiberglass mixed with resins, which prevent good conductivity of heat and electricity. This makes them resistant to melting or degrading when subjected to, or in close proximity of being exposed to, electrical currents. Big machines and factories generate strong electricity; it can be over 1000 volts or more. GPO3 panels take care of that for you since their makeup prevents electricity from jumping or leaking out. They’re highly dielectric, so they resist electrical flow and the risk of shorts or shocks. They’re also not particularly good at absorbing water, key because electricity becomes more hazardous when combined with water. Picture a panel drinking in water like a sponge, not good for safety. Our panels are moisture proof and safe from the humidity. Another important thing is temperature. When you have a flow of electricity, you generate heat.” GPO3: Our white GPO3 can with stand temperatures and it will not weaken at particular heat levels. This keeps them sturdy, durable safe and reliable for prolonged use. We test each batch, and they comply with stringent electrical safety standards, so they can be trusted by consumers. In the real world, this means less trouble with machines stopping or breaking down due to bad electrical panels. So there’s a reason why so many industries choose the GPO3 fiberglass panels from RDS when they need electrical insulation materials

How GPO3 Fiberglass Sheets Help Prevent Overload and Electrical Failures

Overloading occurs when an excessive amount of electricity attempts to flow through a panel or device and creates heat, sparks or even fire. RDS’ GPO3 FIBERGLASS PANELS CAN HELP PREVENT THAT BEFORE BEGINS. They do so in part by distributing the electrical stress evenly across the panel. Rather than allow the electricity to concentrate on one weakened area, the fiberglass structure disperses it around. That decreases the likelihood of one area becoming overwhelmed. For instance, if a machine unexpectedly draws more power than is typical, the panel doesn’t fail because it can handle the heavy load without issue. And our GPO3 panel's surface is smooth, but quite rugged so they are less likely to have dust or dirt adhere - and contribute to electrical paths. Dirty panels are known to result in shorts or overloads, but our approach combats this issue. Cracking or breaking under pressure or heat is yet another characteristic. A broken panel can potentially lead to unsafe electrical failures, but since GPO3 panels are so solid, that doesn’t happen. At RDS we know that panels need to hold up in harsh environments, such as factories with large and heavy machines or outside locations with changing weather. And that’s why we engineer our GPO3 panels to withstand chemicals, water and wear. All of these qualities combine for improved electrical failure reduction. When you trust an RDS GPO3 fiberglass panel, rest assured that your electrical systems will operate reliably and for even longer service time without costly emergency outages. We take time to build these panels properly because we know what safety and dependability mean to our customers

Inappropriate GPO3 Fiberglass Sheets Used for Electrical Loads Common Application Problems

GPO3 fiberglass sheets are widely used fabric in electrical applications which need to safely carry the electric load. But there are a few issues that can arise when people use them improperly, not knowing to be careful around these panels. The problem is that some people do not always know the rated amperage at which GPO3 can be safely used. If an excessive voltage flows through the panel, it may overheat or be damaged. Because each material has a limit as to how much electricity it can manage before becoming unsafe. One other drawback is associated with the environment in which such panels are utilized. GPO3 fiberglass panels are suitable in dry, clean environments (although, if moisture, dust or chemicals are present, its ability to accept electrical loads can be compromised). This can result in short circuits or failures. Improper installation is also an issue for many. When the panels are not installed or linked well, the electricity load may not be distributed uniformly. That can lead to some areas of the panel conducting more electricity than others, perhaps leading to hot spots or damage. But sometimes, the thickness and size of the GPO3 panels into users ignore for their electricity work! Panels too thin or too small cannot bear the load it needs, which creates potential danger. It is imperative, therefore to adhere to the instructions and guidelines for GPO3 fiberglass sheets where electrical loads are concerned. At RDS we ensure your to give you clear information and quality products that will prevent these well known problems. If you know how GPO3 panels work and use them properly, you will ensure safety and reliability for your electrical systems

Why GPO3 Fiberglass Panels Are the Best Choice for Wholesale Electrical Component Fabrication

GPO3 fiberglass panels are commonly selected by companies that produce electrical components in bulk bypass manufacturing, often for wholesale purchasers. This is because one major benefit of a GPO3 panel material is that it’s a great electrical insulator. That they do not allow electricity to pass through them easily, And this is a much needed property when it comes to stopping electric shocks and short circuits. This is the reason why using GPO3 panels to fabricate electrical components ensures that they are safe and high quality. Another factor that drives manufacturers toward GPO3 fiberglass panels is their strength and resistance to wear. GPO3 is produced when fiberglass is combined with plastic in a workflow process that creates a hard panel resistant to heat, pressure and wear over long periods. This makes these panels ideal for electrical components that need to hold up and perform well in challenging environments. Plus, GPO3 has excellent chemical and moisture resistance. This prevents electrical components from being damaged by water or dangerous liquids. For wholesale production, that means fewer returns or complaints – the difference between success and failure in business. GPO3 fiberglass panels are also incredibly easy to work with. They can be cut, drilled and molded with secondary processing without loss of their critical electrical properties. It’s that flexibility that enables manufacturers to produce the many varied types of electric parts rapidly and efficiently. At RDS, we offer high-quality GPO3 fiberglass sheets that meet stringent requirements necessary for producing safe and dependable electrical products. The reason wholesale buyers put their faith in our products is because they are used to produce electrical parts that customers can depend on. In the end, GPO3 fiberglass sheet serves as that perfect middle ground between safety, sturdiness and ease of working with, which is what makes it such a bestseller in wholesale electrical component fabrication

What Wholesale Buyers Need to Know About GPO3 Fiberglass Panels and Electrical Load Performance

How GPO3 Will Perform Under Electrical Loads If you are purchasing these GPO3 fiberglass panels in bulk to use, you should know some of the key components that allow it to act as a non-conductor:We promise each technical information is for specific customers unique purpose. For one, GPO3 panels are capable of withstanding moderate to heavy currents without failing. This is why they can be used to safely conduct electricity in devices, machines or systems that require insulation you can trust. Each GPO3 sheet has a limit, or the dielectric strength. That rating is an indication of how much voltage the panel can handle before it would be at risk of failing. Wholesale customers will want to verify this rating before they decide on panels for their products, as it’s important for both safety and performance. Another crucial criterium is temperature stability. Heat is created when electricity loads itself through panels. RDS GPO3 fiberglass sheets can withstand high temperatures without melting or losing strength. This helps to prevent wear and tear during normal use, and ensures excellent work of the electrical parts. Wholesale buyers should also keep in mind that GPO3 panels need to be installed and handled correctly as well. In wet areas, or against strong chemicals, even the best panels can fail. Selecting panels from a reputable vendor like RDS means you’ll receive quality products with instructions on safe use. Finally, wholesale buyers should also take into account the size and thickness of the GPO3 sheets. Thicker panels tend to better manage higher electrical loads, but they may be more expensive or more difficult to manipulate. Customers have to strike a trade-off between these indicators based on their products. Wholesale purchasers who know these facts will be able to make good decisions with GPO3 fiberglass panels and know that their electrical products will be both safe, durable and valuable. RDS bends over backwards serving buyers with best quality panels and great advice They can trust

Table of Contents

- GPO3 Fiberglass Panels, What Are the Electrical Load Capacity Ratings

- How GPO3 Fiberglass Sheets Help Prevent Overload and Electrical Failures

- Inappropriate GPO3 Fiberglass Sheets Used for Electrical Loads Common Application Problems

- Why GPO3 Fiberglass Panels Are the Best Choice for Wholesale Electrical Component Fabrication

- What Wholesale Buyers Need to Know About GPO3 Fiberglass Panels and Electrical Load Performance

EN

EN