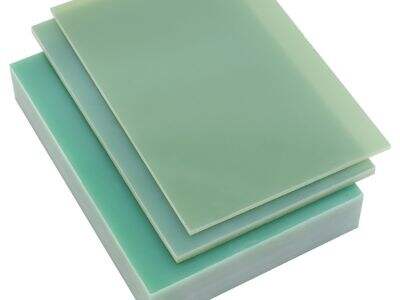

LaminatesThere are special materials called phenolic paper laminates that you find a lot in factories or big industrial places. They are compressed from layers of paper that have been saturated in a type of resin, known as phenolic resin. After being heated and pressed, these layers form a durable, hard board that can withstand rough use. We rely on these laminates at RDS, as they are built to last and perform well under challenging conditions. They can turn up in machines, control panels and even elements of conveyor belts. What makes them so useful is that they are also heat-, water- and chemical-resistant, all common issues in heavy industry. This article will discuss the ways in which phenolic paper laminates are a helpful tool for factories, and some of the challenges that come with using them

How Phenolic Paper Laminates Extend Wear In Demand Heavy Duty Industrial Applications

Here at RDS we consider phenolic paper laminates to be an essential for most industrial requirements. These laminates can take a beating and hold their shape even when machines are shaken or bumped hard. In factories where heavy machines turn all day, for instance, the laminates help save control panels from being scratched and broken. As the paper layers are impregnated with phenolic resin, the laminates become waterproof and do not expand or warp when subjected to moisture. This could be crucial in places like food processing plants, or chemical factories where spills are common. Plus, phenolic laminates can withstand the heat without melting or being set alight easily. This is why they are located near engines or heat sources. This is what phenolic laminates were made for, the panels can withstand pressure from up to 50,000 pounds per square inch without aging or showing wear. Their resistance to chemicals is also significant. Many industrial environments feature strong cleaning agents or acids and phenolic laminates are not susceptible to these as well. That means less frequent repairs and longer-lasting machines or panels covered with this material. At RDS we have already used phenolic laminates and from experience maintenance costs are reduced. And their smooth surface makes them easier to clean, a big consideration in busy factories. Occasionally people think these laminates are heavy or awkward to work with, but our team at RDS has mastered techniques for cutting and shaping them to match any machine part. For that reason, a wide variety of industries count on us to provide durable, strong laminates that continue to work even when things get rough

Typical Issues Encountered in the Industrial Use of Phenolic Paper Laminates

Although phenolic paper laminates are very advantageous, some issues still remain to be addressed. At RDS we hear from customers all the time about a couple of gnarly problems. One problem with these laminate structures is that they are brittle if subjected to rough handling during installation. If they continuously drop or get struck forcefully before being installed, they may break. That means workers have to be cautious when installing them in machines or relocating and repairing this equipment. Another is that phenolic laminates do not bend easily. So, when a machine part must be curve-shaped, more work is required to bend these laminates without snapping them. This may increase the time of production. Additionally, although phenolic laminates are resistant to some chemicals, strong solvents may damage them over time. Factories that work with unusual or very harsh chemicals should check to make sure that the laminate will withstand exposure to them. Heat resistance isn’t always sufficient if it’s simply overmatched by temperatures that exceed what phenolic laminates can take. In these cases, special material would be required or laminates used with other components. Another issue is that phenolic laminates can produce dust when cut, so workers must wear masks and keep the area clean to avoid respiratory issues. At RDS, we educate our staff about these materials to ensure they know how to work with them properly and instruct customers on the proper care of laminates. And, determining the proper thickness and size for specific projects can be challenging to some buyers, but there we come: offering professional advice to ensure the laminates fit correctly and function appropriately. Notwithstanding these problems, the more favorable features may outweigh the difficulties of phenolic paper laminates in industry. They shield machines, thereby saving money on repair and enabling smooth operations. This is why RDS does the work that it does to help perfect how we produce, cut and supply these laminates, because they turn into such a strong and beneficial material used in doing what factories do

Why Phenolic Paper Laminates Are Perfect For Industrial Machinery Parts

SPECIAL CONSTRUCTION Phenolic Paper Laminates are unique materials in the world of engineering plastics: Extraordinary strong and safe; long lasting. At RDS, we make these laminates by pressing together stacks of paper soaked in phenolic resin. The process results in a durable solid sheet that's designed for heavy use. A major reason these laminates are ideal for machines is that they stand up to heat very well. It’s no surprise that phenolic paper laminates don’t melt or distort easily when cars work; they can certainly get hot enough, and most of us have had the unpleasant experience of grabbing a hot seatbelt buckle on a sweltering summer day in an un-air-conditioned car. This means components made of these laminates continue to function in high temperatures

Another key characteristic is its capacity to withstand chemicals and moisture. The machines in factories are frequently exposed to Benin cleaning agents, water or oils. These substances don’t harm phenolic paper laminates, meaning the machine parts live a longer life. They also won’t absorb water, so they resist swelling or cracking. This makes them highly durable in harsh factory conditions

They’re good at halting electricity, these laminates. That means you can safely use them near electrical components, without any risk of short circuits or shocks. For this reason, RDS phenolic paper laminates are frequently employed in the production of machine panels, insulating parts and handles on which workmen's hands come into contact. Third, these laminates are scratch-resistant and do not get damaged easily. They can even withstand heavy weight and friction, meaning parts fabricated from phenolic paper laminates are hard to break or scratch. All of these features make them suitable for industrial machine components

Why Buying Phenolic Paper Laminates in Wholesale is a Cost-efficient Option for Manufacturers

Purchasing phenolic paper laminates in bulk can be an efficient way for manufacturers to save both time and money by going through RDS. Manufacturers that buy in bulk will typically pay less per sheet than a customer buying just a few sheets. This reduction in price is a great advantage, for factories often require a large number of sheets to produce machine parts. Because they can buy in bulk, they could lower the cost of materials, and thereby the total cost of making machines

Wholesale laminates also help to save money by speeding up the production process. Having an ample supply of laminates on hand also means that manufacturers don’t have to wait for new materials to arrive. This enables them to keep their machines running and fulfill orders on time without any holdups. Time is essential in factories, and having enough laminates ready can prevent expensive lines downs

It’s also cheaper because it comes with shipping. Cost of delivery per unit decreases when more sheets are sent at one time, compared to the situation of sending small packages several times. RDS ensures that the bulk orders are packed in a way, when opened it is received intact without any wear and tear. This is a money saver, as it spares manufacturers the expense of replacing shattered substances

And, in addition to the cost savings youll experience by ordering wholesale phenolic paper laminates from RDS, will come the same high level of quality. When manufacturers purchase large quantities of the same trusted supplier, they get laminates that look and perform no differently than the last order. This consistency enables factories to make parts that fit and function exactly right. And with good quality materials, you have less machine failures and repairs which saves even more money in the long run. All in all, the purchase of phenolic flat bottom paper bags wholesale is a value option that allows manufacturers to create powerful and dependable machinery at a low price

How to Choose the Right Industrial Phenolic Paper Laminates

Selecting the best phenolic paper laminates for industrial machines is critical to ensure parts are long-lasting and work well. We help our customers choose laminates here in RDS by focusing on three primary factors. The first thing to consider is the thickness of the laminate. Thicker sheets are stronger and can hold more but may be less easy to cut or form. The thinner the sheet, the easier it is to work with though it may be less strong. Which one you use will depend on what type of machine part you want to make

Next, think about the level of heat resistance required. Some machines heat up to a high temperature, so you need laminates that can withstand the heat without getting overheated or breaking down. RDS provides laminates that have been tested to withstand a range of heat limits, so customers can choose the one best suited to their machines. If the machine operates near chemicals or in water, you will also want to consider laminates that can resist these substances. This is one way to help it last longer and keep it safe

Another factor is electrical insulation. lf the accessory is required to use where electrical wires or circuits may exist, the laminate will have insulating properties so that an electric shock won't be possible. This much electrical resistance is one of the reasons that RDS phenolic paper laminates are safe for partial discharge use

And at last, consider the surface finish. Some laminates feature smooth surfaces that clean easily, while others have textured finishes to help improve grip. Which one is the right choice depends on where and how it will be used. At RDS, we can help steer customers toward the laminate type best suited to these needs. With the appropriate phenolic paper laminate, manufacturers are able to create sturdy and efficient parts that keep machines functioning for a long time

Table of Contents

- How Phenolic Paper Laminates Extend Wear In Demand Heavy Duty Industrial Applications

- Typical Issues Encountered in the Industrial Use of Phenolic Paper Laminates

- Why Phenolic Paper Laminates Are Perfect For Industrial Machinery Parts

- Why Buying Phenolic Paper Laminates in Wholesale is a Cost-efficient Option for Manufacturers

- How to Choose the Right Industrial Phenolic Paper Laminates

EN

EN