How do temperature and humidity affect the dimensional stability of epoxy fiberglass laminate?

The reasons why temperature and humidity affect the dimensional stability of epoxy fiberglass laminate are as follows:

Temperature affect

- Thermal expansion and contraction: Like most materials, epoxy fiberglass laminates exhibit thermal expansion and contraction due to temperature changes.When temperatures rise, increased molecular motion causes molecules to expand in all directions as their average distance grows. Conversely, when temperatures drop, reduced molecular activity leads to molecular compression and laminate contraction. This phenomenon is typically measured by the coefficient of thermal expansion (CTE). Although epoxy fiberglass laminate have relatively low CTE values, significant dimensional changes during extreme temperature fluctuations may still impact high-precision mechanical applications.

- Material Performance Variations: Both excessively high and low temperatures can affect the performance of epoxy fiberglass laminates. For instance, when temperatures approach or exceed their glass transition temperature, the mechanical properties of the panels degrade, becoming more flexible. Under external loads or internal stresses, these plates become more prone to deformation, thereby compromising dimensional stability. In low-temperature environments, the laminates may develop brittleness and reduced toughness, potentially leading to micro-cracks in internal structures. These defects may gradually propagate over prolonged use, ultimately compromising the overall dimensional stability of the laminates.

The effect of humidity

- Hygroscopic Expansion: Epoxy fiberglass laminate exhibit hygroscopic properties. When exposed to high humidity, the boards absorb moisture from the air. As water molecules penetrate the laminate structure, they cause resin matrix swelling and may weaken the interfacial bonding between fibers and resin. This resin swelling leads to dimensional deformation in both thickness and plane dimensions, resulting in measurable size changes. Importantly, the moisture absorption capacity correlates directly with environmental humidity levels – higher humidity intensifies this process, causing more pronounced dimensional variations.

- Mechanical property degradation: Excessive moisture can impair the mechanical performance of epoxy fiberglass laminate, notably reducing their strength and stiffness. When these properties decline, the boards become more prone to deformation under equivalent external forces, which adversely affects dimensional stability. Furthermore, repeated humidity fluctuations may induce internal stress within the boards. Prolonged exposure to such conditions could lead to warping, deformation, and other structural issues, ultimately compromising dimensional integrity.

In order to ensure the dimensional stability of epoxy fiberglass sheets when the ambient temperature and humidity change, we can start from the following aspects:

- Select high quality materials: select reliable and stable epoxy fiberglass sheets. High quality materials are advanced in the formula and production process and better in thermal expansion coefficient, hygroscopicity and other indicators.

- Pre-drying treatment: before use, the sheets can be pre-dried by placing it in a drying environment or using a drying oven and other equipment to remove the moisture contained, so as to reduce the dimensional change caused by hygroscopicity.

- Reserve expansion space: in mechanical design, consider that the sheet may change in size due to temperature and humidity changes, and reserve a certain amount of expansion space for it.

- Structural optimization: improve the dimensional stability of the sheet through reasonable structural design. For example, strengthen the stiffness of the plate by using reinforcement ribs and frame structure, so that it can better resist deformation when temperature and humidity change.

Temperature control: Keep the epoxy fiberglass sheet in a relatively stable temperature range.

Humidity control: use dehumidifier, humidifier and other equipment to control the environmental humidity in an appropriate range. Generally speaking, the environmental humidity is maintained at 40% -60% more suitable.

Coating protection: the surface of epoxy fiberglass sheet is coated with protective coating, such as epoxy resin coating, polyurethane coating, etc.

Chemical treatment: the surface of the sheet is chemically treated to improve the interface bonding performance between the fiber and resin, improve the water resistance and moisture resistance of the sheet, so as to reduce the problem of dimensional instability caused by humidity changes.

In addition, it is necessary to regularly inspect and maintain the epoxy fiberglass laminate, find out the deformation, cracking and other problems caused by temperature and humidity changes in time, and take corresponding repair or replacement measures.

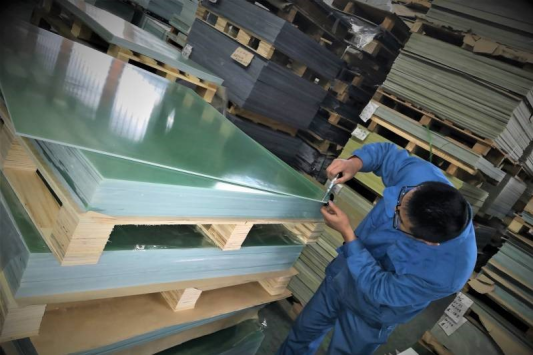

RDS composite has been supplying high-performance epoxy fiberglass products to the market. Its products are carefully managed from raw material procurement through the entire production process to ensure they meet international standards.

EN

EN