Today, Fiberglass pipe is a special material used in many industries. It is a composite of glass fibers reduced to microscopically small size and surrounded by the plastics matrix. Fiberglass offers these two properties neatly in equal measure, making fiberglass pipes doubly valuable and practical. The fiberglass pipes have one of the best advantages that it is much light in weight as compare to metal classed made pipes. They are also relatively strong and can withstand the test of time. This makes them a versatile option for any project. These pipes can take pressure to avoid bursting, which is what you want for certain industrial uses and they are also excellent for chemical work.

The perfect example is the big fiberglass pipes, which are considered to be very helpful in various sectors like oil and gas companies, chemical plants or water treatment plants. The pipes are therefore a practical and clean alternative to the traditional metallic pipes Light weight for easy carry and application. 2). This saves money because they are easier to move by employees and make the workplace safer as there is a much lower chance of accidents. Moreover, rusty and aging in classic along with regular copper pipelines are going the approach of your respective dinosaur mainly because related to more recent technology for fiberglass pipeline implementations do not simply corrode as can steel or wastewater directories. This means that they can withstand a lot without breaking or getting damaged. Hey, and they can last longer than metal pipes also saving you more money for quite some time.

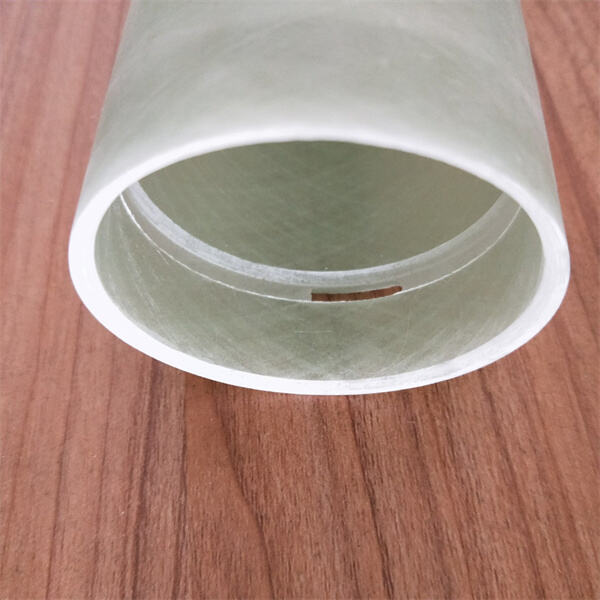

Large fiberglass pipes are one of the crucial things that keep sewer systems, storm drains mines and tunnels operating. These pipes come in a number of shapes and sizes to be crafted into particular requirements for the project. Recent technology has allowed the construction of large pipes, which can be 1 to over four meters in width. This is beneficial to have because it guarantees that we can transport high-volume of water aptly and safely. We need to be using these big pipes in a way that helps us manage more water, now and into the future but also creates better infrastructure for our communities.

Fiberglass pipes have proved to useful in many of fields. It has abilities to carry gases, liquids and also solid materials. Their versatility allows them to be implemented across diverse industries, types of companies and projects. One such example would be that, they help in retaining heat which can be a crucial factor for certain systems working at specific temperatures. Along with this, fiberglass pipes are used extensively in the process of oil extraction for transporting crude to surface. They are suitable for carrying chemicals, slurry etc which may be corrosive and abrasive.

ConclusionThere are so many reasons to use high capital fiberglass pipe. They are durable yet lightweight and therefore, they are best suited for heavy duty tasks in the industrial field. High Heat Resistance & Wear Proof: This means that they are capable of lasting long, even when the use cases is extreme. The manufacturing these pipes has become a lot cheaper and faster with new methods — such as filament winding, through which the reinforcement is wound on to it while passing though some automatic process. This also means that the fabrication of large-diameter fiberglass pipes has never been easier in terms of efficiency and accuracy. With only the latest advancements in technology, now long pipes are mostly made from heavy fiberglass material and these cause them an appropriate selection for most industries to provide stiff tubes.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.