In case you have never come across phenolic resin laminate, This material has many applications because it is a very versatile type of stuff! This article explains the uses and advantages of phenolic resin laminates. You will also find out how they are robust and sturdy, how they can be tailored only for you, and why believe it or not other materials have a difficult time competing with stainless steel in so many jobs.

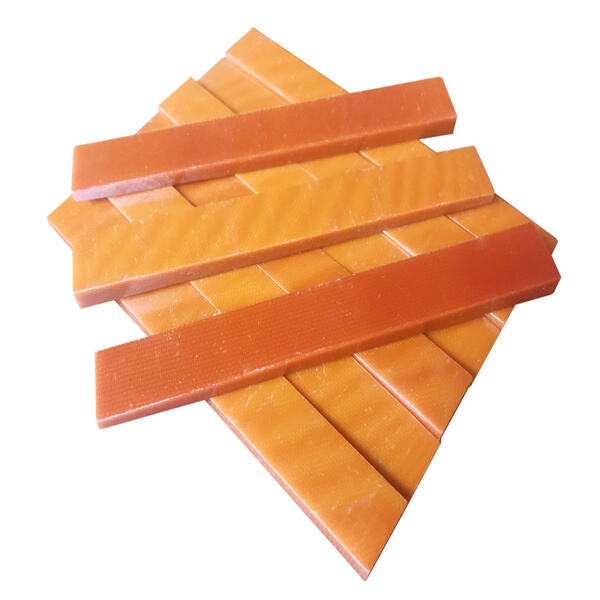

Phenolic resin laminates consist of paper or fabric that is combined with phenolic resins. The layers are stacked and then pressed with heat to bond them. This creates a very durable and hard material which is used in many different applications. Phenolic resin laminates have a lot going for them — they're able to resist water, chemicals and heat. This makes them well-suited in areas like kitchens, laboratories and factories where these are standard conditions.

The insulating laminates can also be isolated using them. Insulation allows us to be safe and comfortable. For instance, they are great for conserving electrical products like transformers and generators. Such oils are great with high heat and flame resistance, due to them being less likely caught on fire. Phenolic resin laminates are highly versatile in the construction industry since they can be molded in numerous shapes. These are used to give buildings strong and weather-friendly foundations, walls, roofs etc., which ensure that the building lasts for a long time.

Phenolic resin laminates are commonly used when the solutions need to be strong. One use case for them is the automotive and aerospace sector, as they are very resistant to heat. This makes them ideal for long-term wear and high-stress applications. Phenolic resin laminates are also used in sport equipment such as skis, snowboards and skate-boards. And those things have to withstand all the activity people do with them, which is why phenolic resin laminates exist.

One thing that makes phenolic resin laminates so astounding is their strength. This makes them really strong and durable to use. What is particularly useful for many applications is that they are able to hold significant weights effortlessly. They might be used in construction, for strength or some other feature. Furthermore, these laminates are impact resistant and dent proof that is it can absorb body blows and impacts without cracking or breaking instantly. This toughness is what makes them useful in a lot of applications.

Also, one more awesome feature of phenolic resin laminates is that they can be manufactured to cater exactly for your requirements. Which means you can customise them to exactly as you like! Different colored dyes in the layers of paper or fabric can be used when producing phenolic resin laminates. This way, you can design the laminates to match your preferences just right. Additionally, they can also be cut to different dimensions like you would design the laminates that will work for your particular project. Phenolic resin laminates are very versatile in that they can be customized for a wide range of purposes, which is why many designers and builders love them.

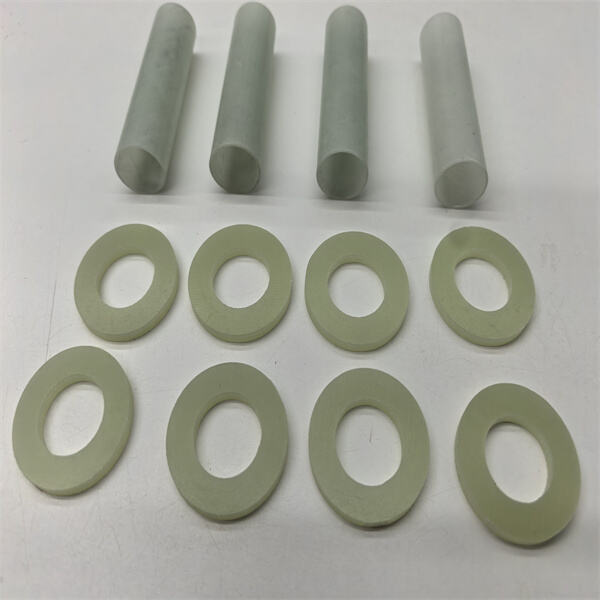

An example is phenolic resin in the electronics industry, where they are used for printed circuit boards. As solder materials, they must be able to survive the high heat involved in reflow and maintain resistance through harsh chemicals combine with whatever process it undergoes during manufacturing. This laminate is used for engine gaskets in the automotive industry. If they handle easily the high temperatures will pressure produced by an engine there is good chance everything will operate properly.

As a professional producer, we offer a wide range of insulating materials, including fiberglass, carbon fiber, cotton fabric, and paper-based laminates, as well as plastic injection and custom composite fabrication services.

We maintain long-term partnerships with sea, air, and rail freight forwarders, providing flexible and efficient shipping solutions to support timely global delivery.

We prioritize timely communication, professional technical assistance, and responsive after-sales service to ensure a seamless experience and lasting satisfaction for our clients worldwide.

With modern equipment, advanced technology, and a team of experienced engineers, we ensure that our products consistently meet international standards and diverse application requirements.