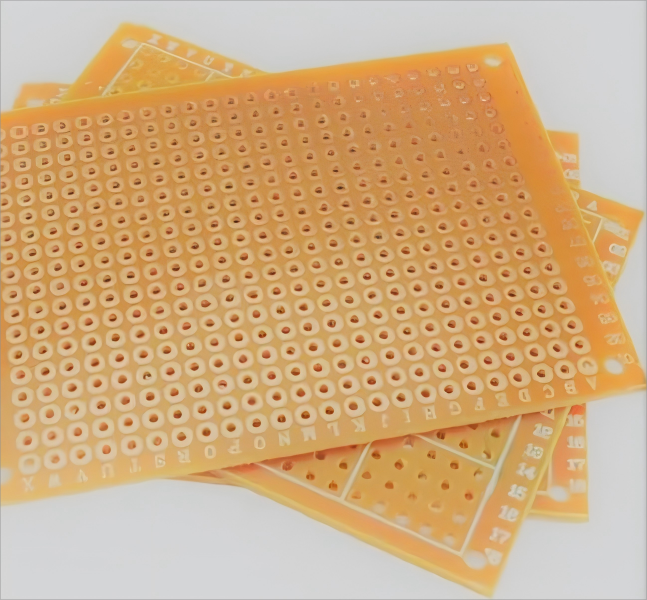

Phenolic Paper Laminates - A Perfect Blend of Economy and Durability

Introduction

Phenolic paper bakelite laminate, often referred to as phenolic laminate or bakelite insulation sheet, is a high-performance electrical insulating material. It is primarily composed of paper substrates impregnated with phenolic resin (bakelite), which is then cured under heat and pressure to form a rigid, thermosetting composite sheet. This material is widely used in electrical and electronic applications due to its excellent insulation properties, mechanical strength, and resistance to heat and chemicals.

Key Properties

1. Electrical Insulation: High dielectric strength and resistance to electrical breakdown, making it suitable for use in transformers, motors, and other electrical equipment.

2. Mechanical Strength: Rigid and durable, with good impact and compressive resistance, allowing it to withstand mechanical stress in structural applications.

3. Thermal Resistance: Can withstand moderate temperatures (typically up to 130°C or higher, depending on the grade) without significant degradation.

4. Chemical Resistance: Resistant to oils, solvents, and many common chemicals, enhancing its suitability for harsh environments.

5. Workability: Can be machined, drilled, or cut into various shapes and sizes to meet specific design requirements.

Manufacturing Process

The production of phenolic paper bakelite laminated sheets involves a multi-step process:

Impregnation:

1. High-quality paper (e.g., craft paper or cotton-based paper) is passed through a bath of liquid phenolic resin, ensuring uniform absorption.

2. Excess resin is removed, and the impregnated paper (called "prepreg") is dried to a semi-cured state (B-stage), where it is still tacky but not fully hardened.

Lamination:

1. Layers of the prepreg are laminated in a mold, with alignment to ensure uniform thickness and consistency.

2. Additional layers or reinforcement (e.g., cloth for enhanced strength) may be included in some formulations.

Curing under Heat and Pressure:

1. The laminated prepreg is placed in a hydraulic press and subjected to high temperature (typically 140–170°C) and pressure (10–30 MPa) for a specified duration (depending on thickness).

2. The heat triggers cross-linking of the phenolic resin, while the pressure ensures tight bonding between layers, forming a solid, homogeneous sheet.

Post-Processing:

1. The cured sheet is trimmed to size, sanded, or polished to achieve the desired surface finish.

2. Quality control checks (e.g., electrical testing, dimensional accuracy) are performed to ensure compliance with standards (e.g., IEC, ASTM).

Applications

· Electrical Equipment: Used as insulating barriers, spacers, or supports in transformers, circuit breakers, and switchgear.

· Motor and Generator Components: Insulates windings and provides structural support in electric motors and generators.

· Industrial Machinery: Used in mechanical parts requiring both insulation and strength, such as gears, bearings, or brackets.

· Consumer Electronics: Found in appliances and devices where electrical insulation and heat resistance are critical.

Standards and Grades

Common standards for phenolic paper bakelite laminates include:

· IEC 60893-3-1: International standard for thermosetting laminates used in electrical applications. According to the IEC standard, phenolic paper - laminated sheets have the following grades: PFCP201, PFCP202, PFCP203, PFCP206, PFCP207.

· NEMA LI 1-1998: American standard specifying requirements for phenolic paper laminates. According to the NEMA standard, phenolic paper - laminated sheets have the following grades: X, XP, XPC, XX, XXP, XXX.

Grades may vary based on resin type, paper quality, and performance criteria (e.g., flame retardancy, moisture resistance).

Advantages

· Cost-effective compared to advanced insulating materials (e.g., epoxy laminates).

· Readily available and easy to machine.

· Balanced performance in electrical, mechanical, and thermal properties.

Conclusion

Phenolic paper bakelite laminated sheets are versatile, reliable materials for medium-voltage electrical and industrial applications. Their combination of insulation, mechanical strength, and cost-effectiveness makes them a staple in power generation, distribution, and manufacturing sectors.

EN

EN