Functions and Materials of Motor Slot Wedges

The motor slot wedge is an important part in the manufacture of motor, it plays a vital role in the normal operation and performance of the motor.

Motor slot wedges are typically installed in the stator slots to secure the stator coils. As one of the motor's key components, these coils generate rotating magnetic fields through current excitation, driving the motor's operation. Without proper slot wedge installed, the coils may loosen during operation, potentially leading to reduced performance or even motor failure.

Motor slot wedges are typically made of insulating materials, such as glass fiber reinforced epoxy resin, which enhances the motor's insulation performance. Improved insulation reduces the risk of motor breakdown in high-voltage or humid environments, thereby enhancing the motor's safety and reliability.

The slot wedge of the motor forms a tight enclosed space around the stator coil, which helps to improve the heat dissipation efficiency of the motor. Good heat dissipation can reduce the temperature of the motor, reduce the thermal stress of the motor under high load conditions, and prolong the service life of the motor.

During operation, motors generate noise and vibration. The slot wedges can effectively mitigate these adverse effects. When stator coils are securely mounted within the slot wedges, they minimize resonance and vibration during operation, thereby reducing noise levels.

The motor slot wedge serves as a protective layer for the stator coil, preventing external objects from entering the slot and avoiding physical damage to the coil. Particularly in harsh industrial environments, such as those with high concentrations of dust, moisture, or chemicals, the presence of the slot wedge can effectively protect the stator coil from damage.

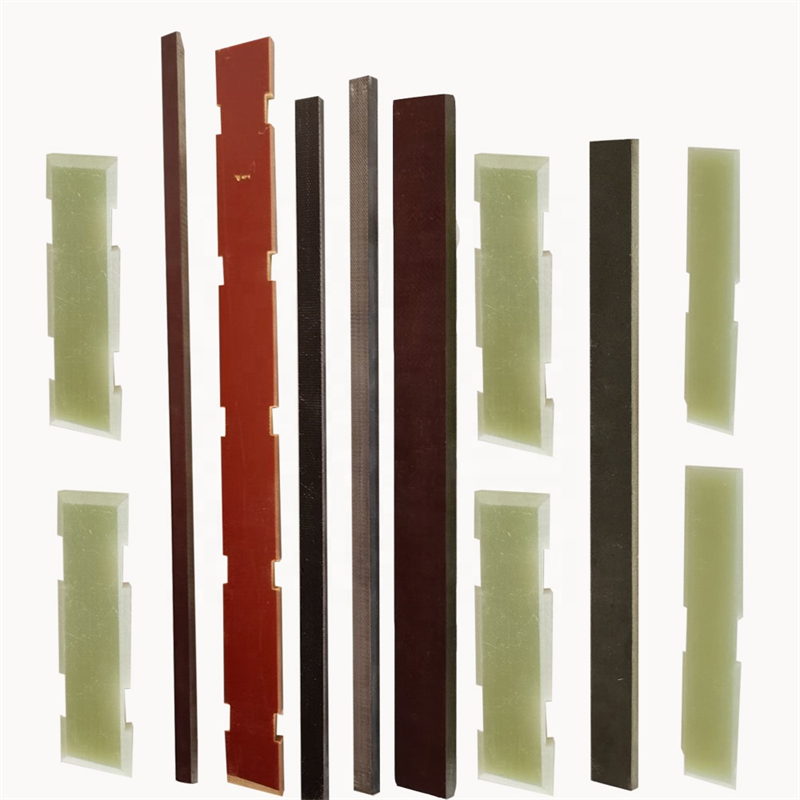

RDS composite can customize the epoxy glass cloth wedge and magnetic slot wedge with various sizes and specifications according to the customer’s drawings.

The epoxy glass cloth slot wedge is manufactured from epoxy glass cloth sheets as the base material. Standard models are rated for F-class heat resistance (155°C), while modified versions can withstand H-class temperatures (180°C).

The magnetic slot wedge is primarily composed of glass fiber cloth, epoxy resin, iron powder, and other additives. The standard model has a heat resistance of F grade (155°C) to H grade (180°C).

EN

EN