Mechanical processing——the cornerstone of manufacturing

Mechanical processing, formally known as machining, is a manufacturing process that modifies the shape, dimensions, surface quality, or properties of raw materials like metal, plastic, and wood using specialized equipment such as lathes, milling machines, and grinding machines. This process ultimately produces components or finished products that meet design specifications. As the cornerstone of modern manufacturing, it finds applications across nearly every industrial sector, including automotive, aerospace, electronics, medical devices, and mold production.

1. Classifications of machining:

According to the processing method, machining is mainly divided into cold processing and hot processing. The core difference between them lies in whether the raw material is heated during the processing process, and there are also significant differences in the application scenarios and processing purposes.

|

class |

definition |

Common processing methods |

Applicable materials and scenarios |

|

Cold processing |

The material is processed at room temperature without changing the metallographic structure (only shape/size), and the processing accuracy is high |

-Cutting: lathe (turning), milling machine (milling), grinding machine (grinding), drilling machine (drilling), boring machine (boring), machining center -Pressure processing: stamping, cold rolling, cold drawing, bending |

Metal (steel, aluminum, copper, etc.), plastic, wood; suitable for high precision, surface finish requirements of components (such as engine shaft, gear, electronic parts housing) |

|

Hot processing |

Processing at a temperature higher than the material's recrystallization temperature will change the material's metallographic structure and properties, which is often used in rough manufacturing or performance optimization |

-Casting: sand casting, die casting, precision casting Forging: free forging, die forging -Welding: arc welding, laser welding, brazing -Heat treatment: quenching, tempering, annealing (does not change the shape, but is an auxiliary process of heat processing for optimization of performance) |

Metal (cast iron, cast steel, aluminum alloy, etc.); suitable for manufacturing complex shaped blanks (such as engine cylinder body, machine tool bed) or improving the strength/hardness of materials (such as tool quenching) |

2. Common machining equipment and process

Lathes (turning):

Core functions: workpiece rotation (main motion), tool linear movement (feed motion), mainly processing rotary parts (round, cylindrical, conical).

Typical applications: processing shafts (such as motor shaft), discs (such as flanges, gear blanks), sleeve parts, can complete lathe round, lathe end face, drilling, tapping, lathe thread and other operations.

Milling machine (milling):

Core functions: tool rotation (main motion), workpiece movement (feed motion), can be processed plane, groove, complex contour (such as gear tooth shape, mold cavity).

Classification: vertical milling machine (tools are vertically downward), horizontal milling machine (tools are horizontally placed); CNC milling machine can realize multi-axis linkage, processing more complex three-dimensional shapes.

Grinding machine (grinding):

Core function: Using "sand wheel" (high-speed rotating tool) to carry out fine cutting on the surface of the workpiece, it is the key equipment for high precision and high finish processing.

Typical applications: grinding plane (planing bed), outer circle (out circle grinding bed), inner hole (inner circle grinding bed), often used in the "final finishing" of parts (such as bearing inner and outer rings, precision guide rails), precision up to 0.001mm.

Drill and boring machine:

Drill: mainly used for drilling, enlarging, reaming and tapping holes on workpieces. Common types include table drill (small workpieces) and rocker arm drill (large/heavy workpieces).

Boring machine:

Used for machining large diameter holes, precision holes or hole series (such as machine tool spindle hole, engine cylinder bore), can correct the position error of holes, ensure the coaxiality and verticality of holes.

CNC Machining Center:

Definition: a CNC automation equipment integrating lathe, milling machine, drilling machine and other functions, equipped with tool magazine (automatic tool change), can complete multiple processing processes at one time.

CNC can reduce the number of workpiece clamping (reducing positioning error), improving processing efficiency and precision, is the core equipment of modern batch production and complex part processing, divided into vertical machining center, horizontal machining center, five-axis machining center (can process complex curved surfaces at any Angle).

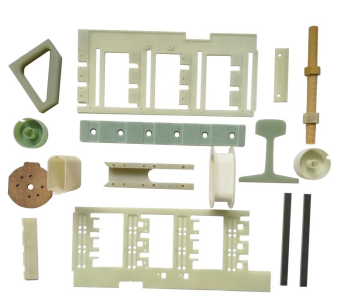

Over the years, RDS had invested in advanced machines and professional tools for the machining of thermoset composites. We operate more than 100 sets of different types of CNC machines and processing machines such as milling machine, drilling machine, sawing machine, punching machine, sanding machine and so on.

With professional order management, rich experienced engineers and welleducated staff, RDS always provides the uniform and high level of machining components for worldwide customers. RDS has machining capacity to meet the customers’ requirements for both quality and delivery timelines.

EN

EN